FRP yeeb nkab yog ib hom tshiab ntawm cov khoom sib xyaw, nws cov txheej txheem tsim khoom yog tsim los ntawm cov ntsiab lus siab ntawm iav fiber ntau winding txheej los ntawm txheej raws li cov txheej txheem, Nws yog tsim tom qab kub kub curing.Cov txheej txheem phab ntsa ntawm cov kav dej FRP yog qhov tsim nyog thiab qib siab dua, uas tuaj yeem muab kev ua si tag nrho rau lub luag haujlwm ntawm cov khoom siv xws li iav fiber ntau, resin thiab curing tus neeg saib xyuas, uas tsis tsuas yog ua tau raws li lub zog thiab rigidity siv, tab sis kuj ua kom ruaj khov thiab kev ntseeg tau ntawm FRP cov kav dej.

Technical yam ntxwv

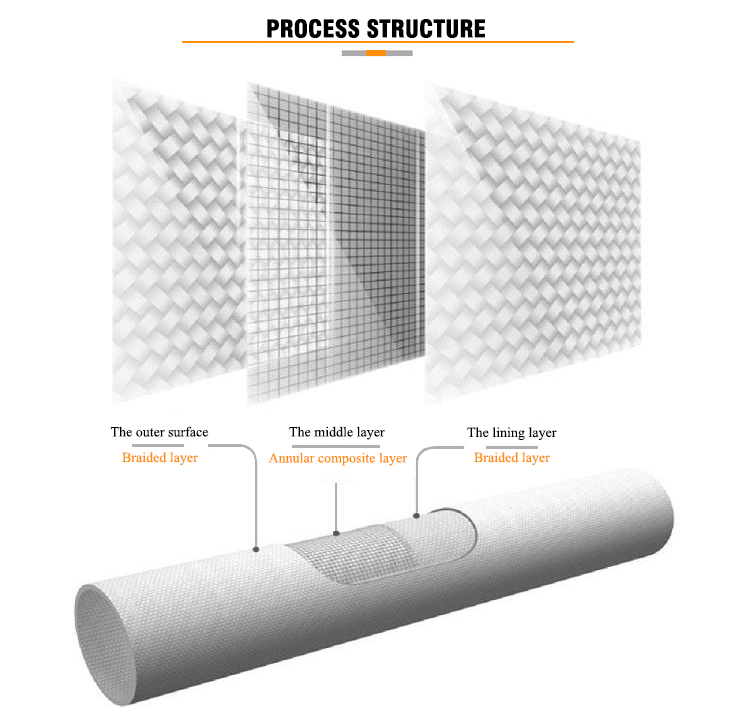

1.Nruam winding ntau lawm txheej txheem

Txoj kev nruam winding molding yog muab faib ua peb hom: qhuav winding, ntub winding thiab semi-qhuav winding raws li lub cev thiab tshuaj lub xeev ntawm cov resin matrix thaum fiber winding molding.Qhuav winding yog siv cov xov paj prepreg los yog daim kab xev uas tau kho prepreg, uas yog rhuab rau ntawm lub tshuab winding kom soften nws mus rau ib tug viscous kua xeev thiab ces kis mus rau ib tug tseem ceeb pwm.Qhov loj tshaj plaws ntawm cov txheej txheem qhuav winding yog nws cov kev ua haujlwm siab ntau lawm thiab qhov nrawm nrawm tuaj yeem ncav cuag 100-200m / min;cov ntaub ntub dej yog ua kom cua ncaj qha rau cov khoom siv fiber ntau (xov paj zoo li daim kab xev) ntawm lub mandrel hauv kev tswj nruj tom qab tau dipped hauv cov kua nplaum;Qhuav winding yuav tsum tau ntxiv cov khoom ziab kom tshem tawm cov kuab tshuaj hauv cov xov paj tom qab cov fiber ntau dipped rau hauv cov pwm pwm.

2.Internal curing molding txheej txheem

Txoj kev kho sab hauv yog txheej txheem molding zoo rau cov khoom siv thermosetting fiber ntau.Cov pwm tseem ceeb uas yuav tsum tau ua rau cov txheej txheem kho sab hauv yog cov qauv cylindrical hollow, thiab ob qhov kawg yog tsim los nrog qee qhov taper los pab txhawb kev demolding.Lub hollow steel yeeb nkab yog coaxially ntsia rau hauv cov tub ntxhais pwm, uas yog, cua sov Rau cov tub ntxhais tube, ib kawg ntawm cov tub ntxhais raj yog kaw, thiab lwm kawg yog qhib raws li ib tug chav inlet.Cov qhov me me tau muab faib rau ntawm phab ntsa ntawm lub raj tub ntxhais.Cov qhov me me yog symmetrically faib nyob rau hauv plaub quadrants los ntawm axial seem.Cov tub ntxhais pwm tuaj yeem tig ib ncig ntawm lub ncej, uas yooj yim rau winding.

3.Demoulding system

Yuav kom kov yeej ntau yam tsis zoo ntawm phau ntawv demolding, niaj hnub iav steel yeeb nkab ntau lawm kab tau tsim ib qho kev tsis siv neeg demolding system.Cov txheej txheem ntawm lub tshuab demolding feem ntau yog tsim los ntawm cov khoom siv demolding, lub tog raj kheej kaw, ib qho kev sib txhuam demolding, ib tug pas nrig thiab pneumatic system.Lub demolding trolley yog siv los zawm cov tub ntxhais pwm thaum lub sij hawm winding, thiab lub tog raj kheej raug kaw thaum demolding.Lub piston pas nrig yog retracted, lub clamping steel pob tsa nyob rau hauv lub tailstock sab yog muab tso rau, lub spindle yog loosened, thiab ces cov demolding kev sib txhuam tongs ua tiav cov txheej txheem spindle clamping los ntawm kev sib txhuam quab yuam ntawm spindle tig thiab lub tog raj kheej, thiab thaum kawg xauv lub tog raj kheej thiab cov demolding txhuam txhuam cais lub raj lub cev los ntawm cov tub ntxhais pwm nrog rau lwm yam khoom siv kom tiav cov txheej txheem demolding.

Kev txhim kho yav tom ntej

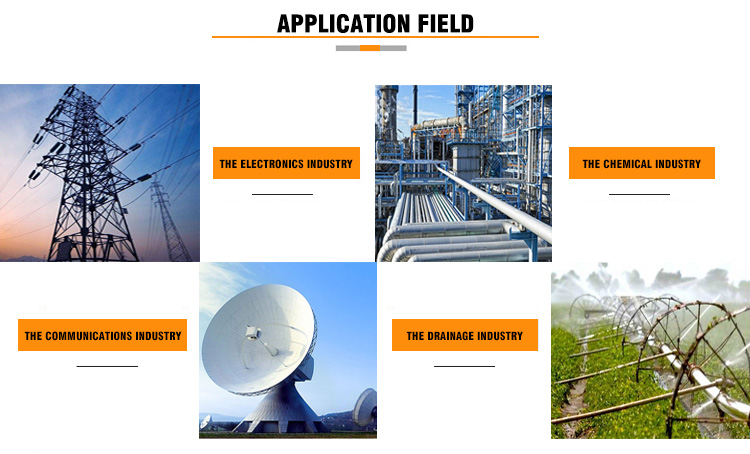

Cov khoom siv dav siv rau thaj chaw thiab chaw lag luam loj

FRP pipelines yog tsim tau heev thiab tuaj yeem ua tau raws li cov kev xav tau ntawm ntau lub teb.Cov ntawv thov kev lag luam suav nrog kev tsim khoom nkoj, kev tsim khoom siv hluav taws xob marine engineering, petrochemical, nkev roj, hluav taws xob, dej thiab dej, hluav taws xob nuclear, thiab lwm yam, thiab kev lag luam xav tau loj.

Lub sij hawm xa tuaj: Plaub Hlis-27-2021