Ntxiv cov hlaws iav hollow rau cov khoom siv roj hmab tuaj yeem coj ntau yam zoo:

1, Txo qhov hnyav

Cov khoom siv roj hmab kuj yog rau kev sib dua thiab ruaj khov, tshwj xeeb tshaj yog kev siv cov roj hmab microbeads laus, los ntawm qhov ceev ib txwm muaj li ntawm 1.15g / cm³ lossis li ntawd, ntxiv 5-8 qhov ntawm microbeads, txo qis rau 1.0g / cm³ (feem ntau hu ua "ntab ntawm dej"), muaj qee qib ntawm R & D peev xwm ntawm cov neeg siv khoom los ntawm kev ntxiv microbeads yuav muaj qhov ceev ntawm 0.9 lossis txawm tias 0.85g / cm³, txo qhov ceev ntawm roj hmab, khau thiab tib qhov xwm txheej ua ntej qhov hnyav txo qis li ntawm 20%. Tam sim no, qee tus neeg siv khoom uas muaj qee qhov kev txawj ntse R & D yuav ua rau qhov ceev ntawm 0.9 lossis txawm tias 0.85g / cm³ los ntawm kev ntxiv microbeads, uas txo qhov ceev ntawm roj hmab, thiab qhov hnyav ntawm khau yuav raug txo los ntawm kwv yees li 20% nyob rau hauv tib qhov xwm txheej zoo li ua ntej.

2, Kev rwb thaiv cua sov

Cov qauv hollow ntawm cov hlaws iav hollow muab cov hlaws dai rau qhov kub tsis tshua muaj thermal conductivity, vim tias cov khoom siv thermal conductivity qis ntxiv rau cov khoom siv roj hmab tuaj yeem ua si zoo heev thermal rwb thaiv tsev, xws li hauv cov ntaub qhwv thermal rwb thaiv tsev, cov laug cam thermal rwb thaiv tsev thiab lwm yam khoom siv.

3, Kev nqus suab thiab txo suab nrov

Sab hauv cov hlaws iav khoob yog cov roj nyias nyias, cov suab nthwv dej hauv qhov no yuav qaug zog, ntxiv rau qee qhov kom ua si zoo heev rau kev nqus suab thiab txo suab nrov.

4, Kev ruaj khov zoo

Cov khoom siv hlaws dai yog iav nrog cov coefficient qis ntawm thermal expansion, zoo dimensional stability thaum raug thermal shock, ntxiv rau cov roj hmab khoom yuav muab cov khoom zoo dua dimensional stability.

Cov lus qhia rau kev siv rau hauv kev ua cov txheej txheem:

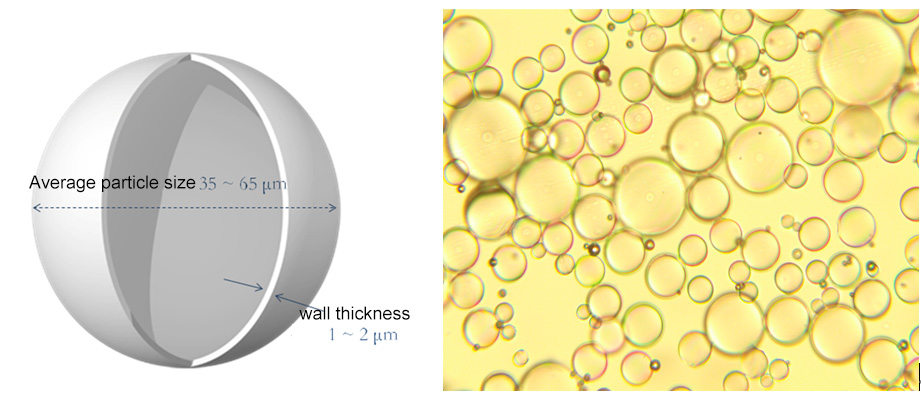

1, cov khoom siv ua cov khoom siv roj hmab feem ntau yog cov khoom siv refiner, opener, ib lub extruder, thiab lwm yam., Vim tias cov hlaws dai yog cov khoom siv iav phab ntsa koom nrog cov khoom tawv, ua lub luag haujlwm ntawm lub zog shear mechanical yuav tawg ib nrab, cov hlaws dai yuav poob nws cov haujlwm tshwj xeeb tom qab tawg.

2, cov hlaws dai iav hollow muaj cov qauv sib txawv thiab cov yam ntxwv sib xws, raws li cov khoom siv sib txawv thiab cov khoom xav tau los xaiv cov khoom hlaws dai zoo yog qhov tseem ceeb heev, St. Leite pom zoo kom siv HL38, HL42, HL50, HS38, HS42 hauv cov khoom roj hmab.

3, thaum siv rau hauv lub tshuab ua kom zoo, muaj lub rotor ntawm cov khoom siv roj hmab shear, cov hlaws dai tsis tuaj yeem zam los ntawm lub zog shear, yog li kom deb li deb tau kom txo lub sijhawm ntawm cov hlaws dai hauv kev ua kom zoo, nws raug pom zoo kom ntxiv rau hauv kev ua kom zoo lig kom ntseeg tau tias cov hlaws dai ntxiv rau kev ua kom zoo 3-5 feeb tuaj yeem tawg sib npaug; hauv lub tshuab ua kom zoo, qhov sib nrug ntawm cov menyuam thiab lub sijhawm ua kom zoo ntawm kev sib tsoo ntawm cov hlaws dai muaj qhov cuam tshuam ntau dua, nws raug pom zoo tias qhov sib nrug ntawm cov menyuam> 2 hli, lub sijhawm ua kom zoo yuav tsum tsis txhob ntev dhau; Lub zog shear tag nrho ntawm ib lub ntsia hlau extruder yog me me, hais lus zoo, qhov cuam tshuam rau cov microbeads yog me me, nws raug pom zoo kom nce qhov kub extrusion los ntawm 5 ℃, txo qhov viscosity ntawm cov khoom yog qhov zoo dua rau extrusion molding, txo cov microbeads tawg.

Lub sijhawm tshaj tawm: Lub Xya Hli-21-2023