Ntxiv hollow iav hlaws rau cov khoom siv roj hmab tuaj yeem coj tau ntau yam zoo:

1 、 Qhov hnyav txo

Cov khoom siv roj hmab kuj mus rau lub teeb yuag, kev taw qhia ruaj khov, tshwj xeeb tshaj yog cov ntaub ntawv loj ntawm microbeads rubber soles, los ntawm cov pa ntom ntom ntawm 1.15g / cm³ lossis yog li, ntxiv 5-8 feem ntawm microbeads, txo rau 1.0g / cm³ (feem ntau hu ua " ntab rau hauv dej "), muaj qee qhov R & D muaj peev xwm ntawm cov neeg siv khoom los ntawm kev ntxiv microbeads yuav ceev ntawm 0.9 lossis txawm tias 0.85g / cm³, txo qis qhov ntom ntawm cov roj hmab, khau thiab cov xwm txheej zoo ib yam ua ntej qhov hnyav. ntawm 20% los yog li ntawd.Tam sim no, qee cov neeg siv khoom uas muaj peev xwm R & D yuav ua rau qhov ceev ntawm 0.9 lossis txawm tias 0.85g / cm³ los ntawm kev ntxiv cov microbeads, uas txo cov roj hmab ntau heev, thiab qhov hnyav ntawm cov khau yuav raug txo los ntawm 20% nyob rau tib lub sijhawm. xwm txheej ua ntej.

2. Thaum tshav kub kub rwb thaiv tsev

Lub hollow qauv ntawm hollow iav hlaws muab cov hlaws dai kom tsis muaj thermal conductivity, raws li cov khoom siv thermal conductivity tsawg ntxiv rau cov khoom siv roj hmab tuaj yeem ua rau cov thermal rwb thaiv tsev zoo heev, xws li hauv cov thermal rwb thaiv tsev pads, thermal rwb thaiv tsev boards thiab lwm yam khoom siv. .

3 、 Lub suab nqus thiab txo suab nrov

Nyob rau hauv lub hollow iav hlaws dai yog nyias roj, suab yoj nyob rau hauv qhov chaw no yuav tsis muaj zog, nyob rau hauv ib tug tej yam ntxiv mus ua si ib tug zoo heev nyhuv ntawm lub suab nqus thiab suab nrov txo.

4 、 Kev ruaj ntseg zoo

Beads puag khoom yog iav nrog tsawg coefficient ntawm thermal expansion, zoo seem stability thaum raug thermal poob siab, ntxiv rau cov khoom siv roj hmab yuav muab cov khoom zoo dua dimension stability.

Cov lus qhia rau kev siv hauv kev ua:

1, Roj hmab cov khoom lag luam yog feem ntau cov khoom siv hluav taws xob tsis zoo, thiab lwm yam ntawm cov khoom siv tshuab hluav taws xob yuav yog qee qhov tawg, cov hlaws yuav poob nws tshwj xeeb functionality tom qab tawg.

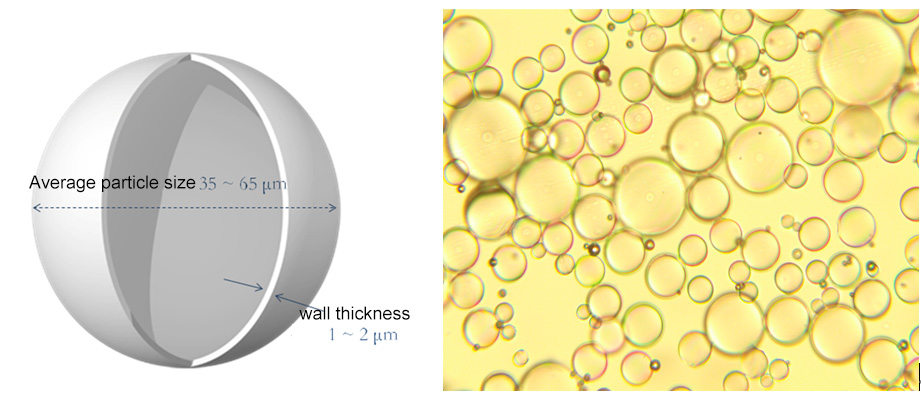

2, hollow iav hlaws muaj cov qauv sib txawv thiab cov tsis sib xws, raws li cov khoom sib txawv thiab cov khoom yuav tsum tau xaiv cov khoom siv hlaws zoo yog qhov tseem ceeb heev, St. Leite pom zoo kom siv HL38, HL42, HL50, HS38, HS42 hauv cov khoom siv roj hmab.

3, thaum siv lub tshuab ua kom zoo, muaj lub rotor ntawm cov khoom siv roj hmab shear, cov hlaws tsis tuaj yeem zam los ntawm lub zog shear, kom deb li deb tau kom txo tau lub sij hawm ntawm cov hlaws hauv kev ua kom zoo, nws raug nquahu kom ntxiv rau. lub sij hawm refining kom paub meej tias cov hlaws dai ntxiv rau refining 3-5min yuav dispersed uniformly;nyob rau hauv lub tshuab refining, cov menyuam qhov sib nrug thiab lub sij hawm refining ntawm crushing ntawm cov hlaws dai muaj kev cuam tshuam ntau dua, nws pom zoo tias cov menyuam qhov sib nrug> 2 hli, lub sijhawm ua kom zoo yuav tsum tsis txhob ntev dhau;Zuag qhia tag nrho shear quab yuam ntawm ib qho ntsia hlau extruder yog me me, kuj hais lus, qhov cuam tshuam ntawm microbeads yog me me, nws raug nquahu kom nce qhov kub ntawm extrusion los ntawm 5 ℃, txo cov viscosity ntawm cov khoom yog ntau conducive rau extrusion molding, txo cov microbeads. tawg.

Post lub sij hawm: Lub Xya hli ntuj-21-2023