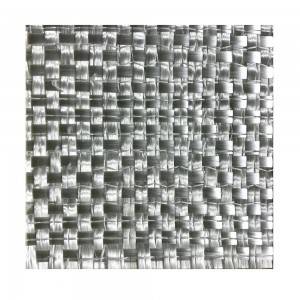

Tek Mat

Kev piav qhia txog khoom

Ib daim lev ua los ntawm cov iav sib xyaw ua ke uas siv hloov daim lev NIK uas xa tuaj txawv teb chaws.

Cov yam ntxwv ntawm cov khoom

1. txawm tias cov fiber dispersion;

2. du nto, mos tes xis;

3. ntub dej sai sai;

4. zoo molding conformability.

Cov Lus Qhia Txog Kev Siv

| Tus lej khoom | Qhov hnyav ib chav | Dav | Cov ntsiab lus ntawm phau ntawv | Cov dej noo | Cov Txheej Txheem thiab Cov Ntawv Thov | |||||||

| g/m² | mm | % | % | |||||||||

| QX110 | 110 | 1250/1500 | 8-10% | ≤0.2 | Cov txheej txheem pultrusion | |||||||

| QC130 | 130 | 1250/1500 | 8-10% | ≤0.2 | Cov txheej txheem pultrusion | |||||||

Ntim Khoom

Txhua lub yob raug qhwv rau ntawm lub raj ntawv. Txhua lub yob raug qhwv rau hauv zaj duab xis yas thiab tom qab ntawd ntim rau hauv lub thawv ntawv. Cov yob raug teeb tsa kab rov tav lossis ntsug rau ntawm cov pallets. Qhov loj me thiab txoj kev ntim khoom tshwj xeeb yuav tsum tau tham thiab txiav txim siab los ntawm tus neeg siv khoom thiab peb.

Storge

Tshwj tsis yog tias tau teev tseg lwm yam, cov khoom fiberalass yuav tsum khaws cia rau hauv qhov chaw qhuav, txias thiab tsis muaj dej noo. Qhov kub thiab txias zoo tshaj plaws yuav tsum tswj hwm ntawm -10 ° ~ 35 ° thiab <80% feem, Txhawm rau kom muaj kev nyab xeeb thiab tsis txhob puas tsuaj rau cov khoom. Cov pallets yuav tsum tau muab tso rau hauv pawg tsis pub ntau tshaj peb txheej siab. Thaum cov pallets raug muab tso rau hauv ob lossis peb txheej, yuav tsum tau ceev faj tshwj xeeb kom txav cov pallet sab saud kom raug thiab du.