-

E-iav Sib Dhos Roving Rau Chopping

1. Txheej nrog cov silane-raws li qhov loj me, sib xws nrog UP thiab VE, xa cov resin absorbability siab thiab choppability zoo heev,

2. Cov khoom sib xyaw ua ke kawg xa cov dej tsis kam thiab tshuaj tiv thaiv xeb zoo heev.

3. Feem ntau siv los tsim cov kav dej FRP. -

Roving Ncaj Qha Rau Kev Hloov Pauv

1. Nws yog sib xws nrog unsaturated polyester, vinyl ester thiab epoxy resins.

2. Nws cov cuab yeej zoo heev ua rau nws haum rau cov khoom fiberglass, xws li daim ntaub roving, cov lev sib xyaw ua ke, cov lev stitched, cov ntaub ntau-axial, geotextiles, molded grating.

3. Cov khoom siv kawg yog siv dav hauv kev tsim kho thiab kev tsim kho, cua zog thiab cov ntawv thov yacht. -

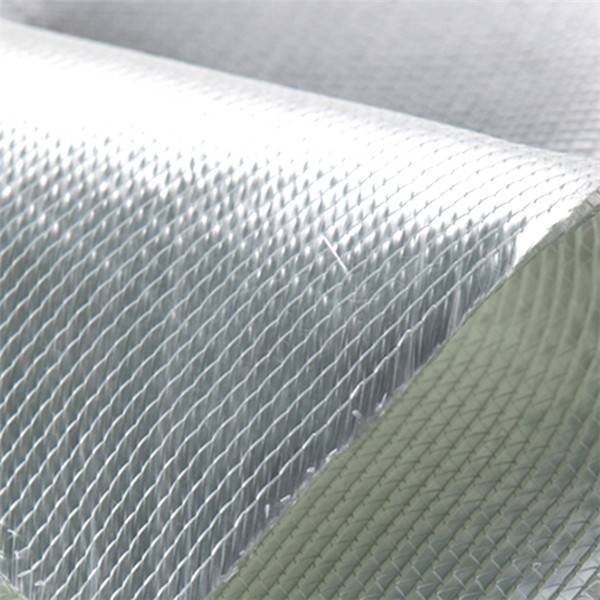

Kev Roving Ncaj Qha Rau Pultrusion

1. Nws yog coated nrog ib tug silane-raws li sizing sib xws nrog unsaturated polyester, vinyl ester thiab epoxy resin.

2. Nws yog tsim los rau filament winding, pultrusion, thiab weaving daim ntawv thov.

3. Nws yog tsim rau siv rau hauv cov kav dej, cov hlab ntsha siab, cov gratings, thiab cov profiles,

thiab cov xov paj rwb uas hloov pauv los ntawm nws yog siv rau hauv cov nkoj thiab cov thoob dej tshuaj lom neeg -

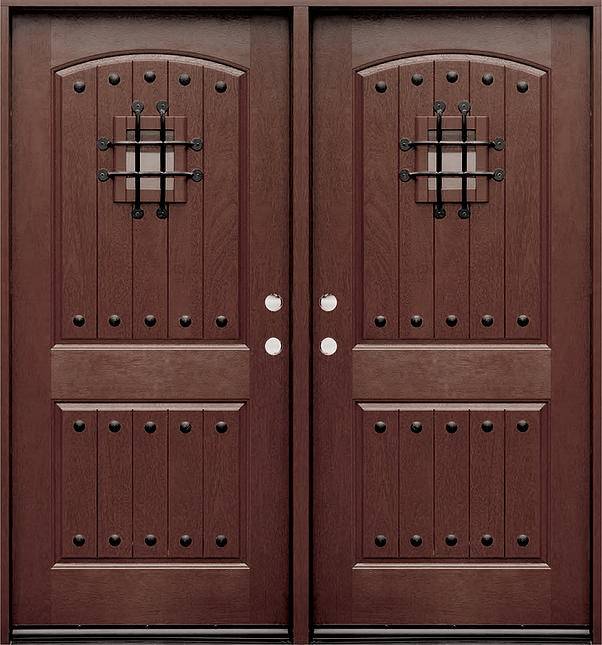

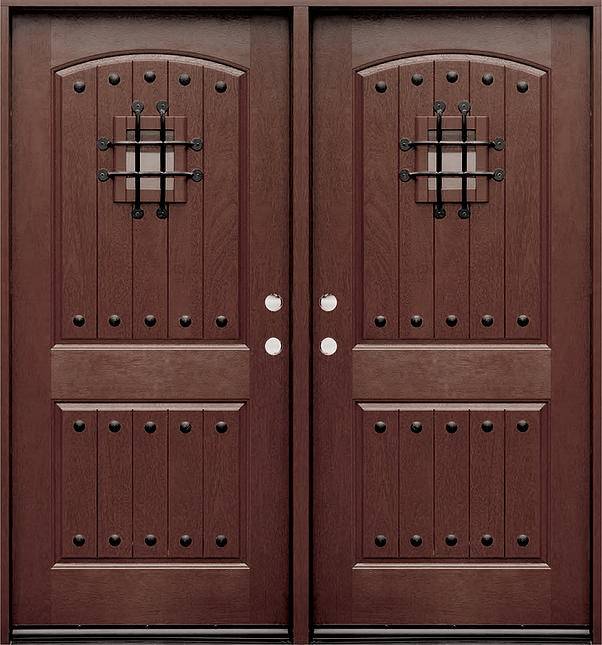

Qhov Rooj FRP

1. Lub qhov rooj tshiab uas tsis ua rau ib puag ncig puas tsuaj thiab txuag hluav taws xob, zoo dua li cov qub uas ua los ntawm ntoo, hlau, txhuas thiab yas. Nws yog ua los ntawm daim tawv nqaij SMC muaj zog heev, lub plawv ua npuas polyurethane thiab lub thav duab plywood.

2. Nta:

txuag hluav taws xob, zoo rau ib puag ncig,

rwb thaiv tshav kub, lub zog siab,

lub teeb yuag, tiv thaiv xeb,

zoo weatherability, dimensional stability,

lub neej ntev, ntau yam xim thiab lwm yam. -

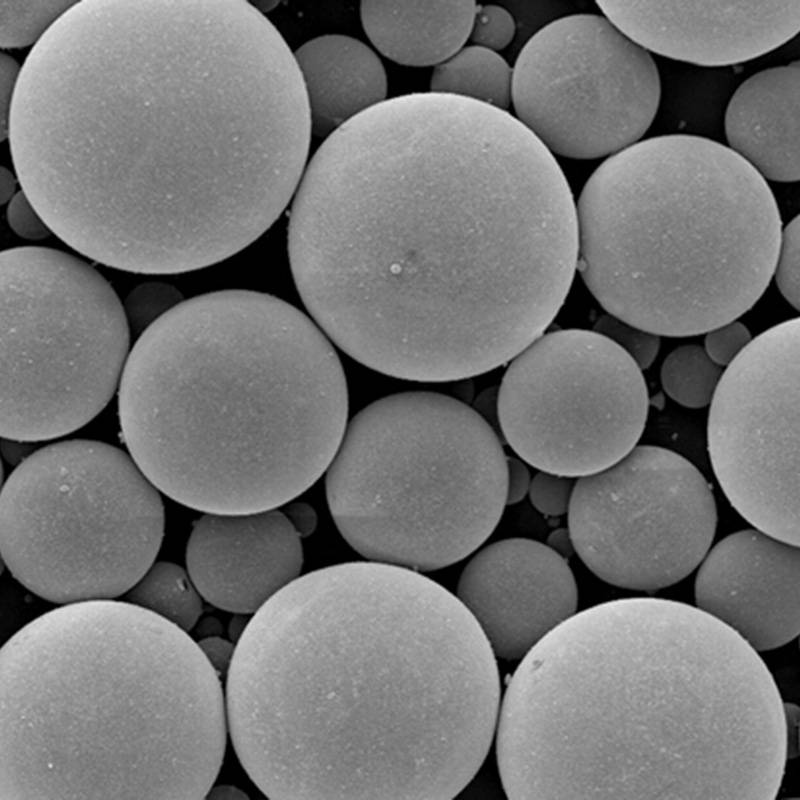

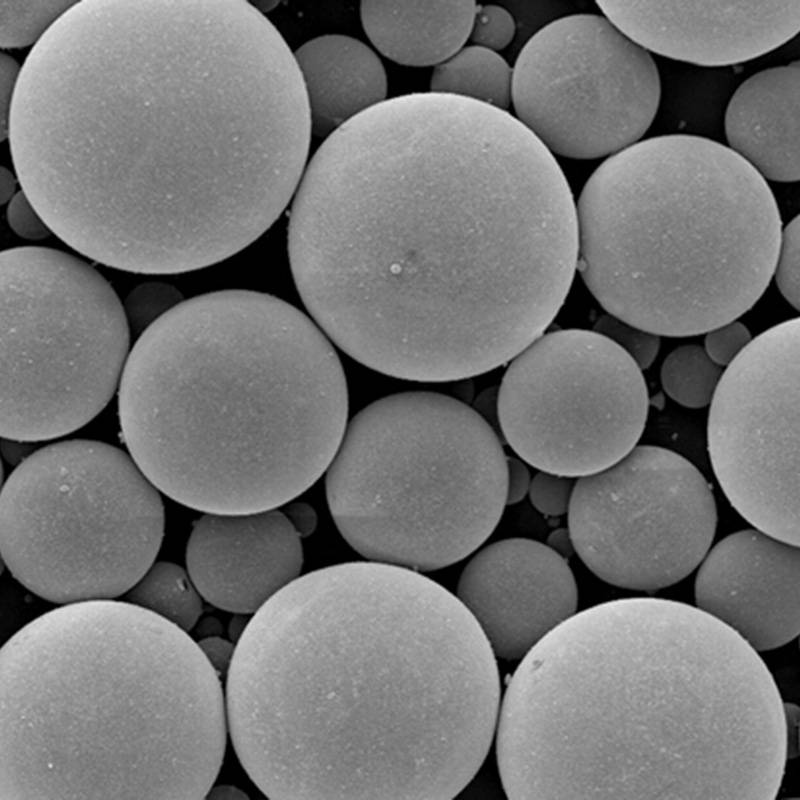

Cov Iav Hollow Microspheres

1. Ultra-light inorganic non-metallic hmoov nrog hollow "pob-bearing" duab,

2. Hom tshiab ntawm cov khoom siv ua haujlwm siab thiab siv dav -

Cov Fiberglass Uas Tau Ua Los Ntawm Milled

1. Cov iav fiber ntau yog ua los ntawm E-iav thiab muaj cov fiber ntev nruab nrab ntawm 50-210 microns.

2. Lawv tau tsim tshwj xeeb rau kev txhawb nqa cov thermosetting resins, thermoplastic resins thiab rau kev pleev xim

3. Cov khoom tuaj yeem raug coated lossis tsis-coated los txhim kho cov khoom siv kho tshuab, cov khoom siv abrasion thiab qhov tsos ntawm qhov chaw. -

S-Iav Fiber muaj zog heev

1. Piv nrog E iav fiber,

30-40% siab dua lub zog tensile,

16-20% siab dua modulus ntawm elasticity.

10 npaug ntau dua kev tiv taus kev nkees,

100-150 degree kub dua nyiaj,

2. Tiv thaiv kev cuam tshuam zoo heev vim nws ntev mus txog thaum tawg, laus sai thiab tiv thaiv kev xeb, thiab cov khoom ntub sai sai. -

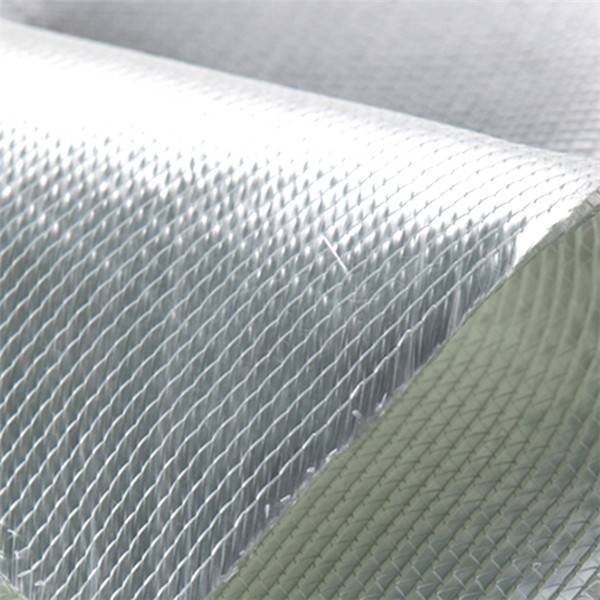

Quataxial (0 ° + 45 ° 90 ° -45 °)

1. Feem ntau 4 txheej ntawm kev roving tuaj yeem xaws tau, txawm li cas los xij ib txheej ntawm cov xov txiav (0g / ㎡-500g / ㎡) lossis cov ntaub ntawv sib xyaw tuaj yeem ntxiv.

2. Qhov dav tshaj plaws tuaj yeem yog 100 nti.

3. Nws yog siv rau hauv cov hniav ntawm lub zog cua turbines, kev tsim nkoj thiab kev qhia txog kev ua si. -

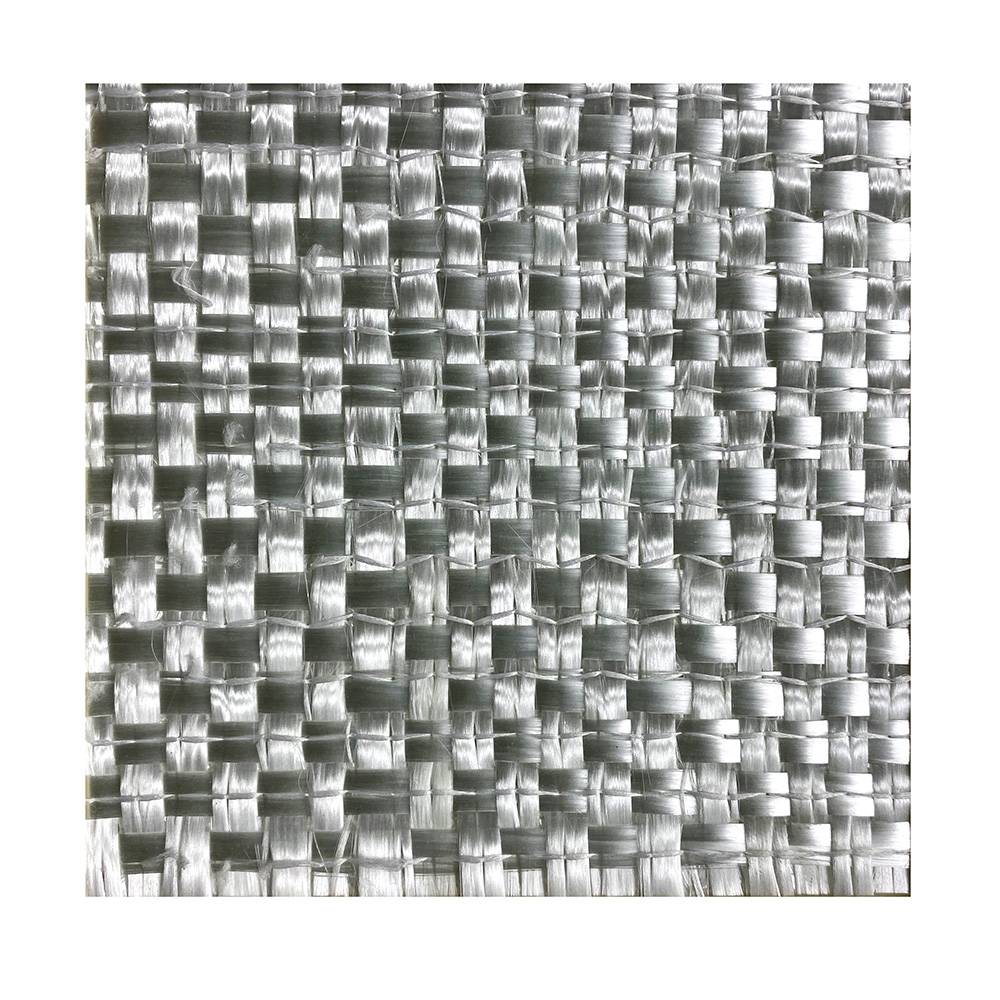

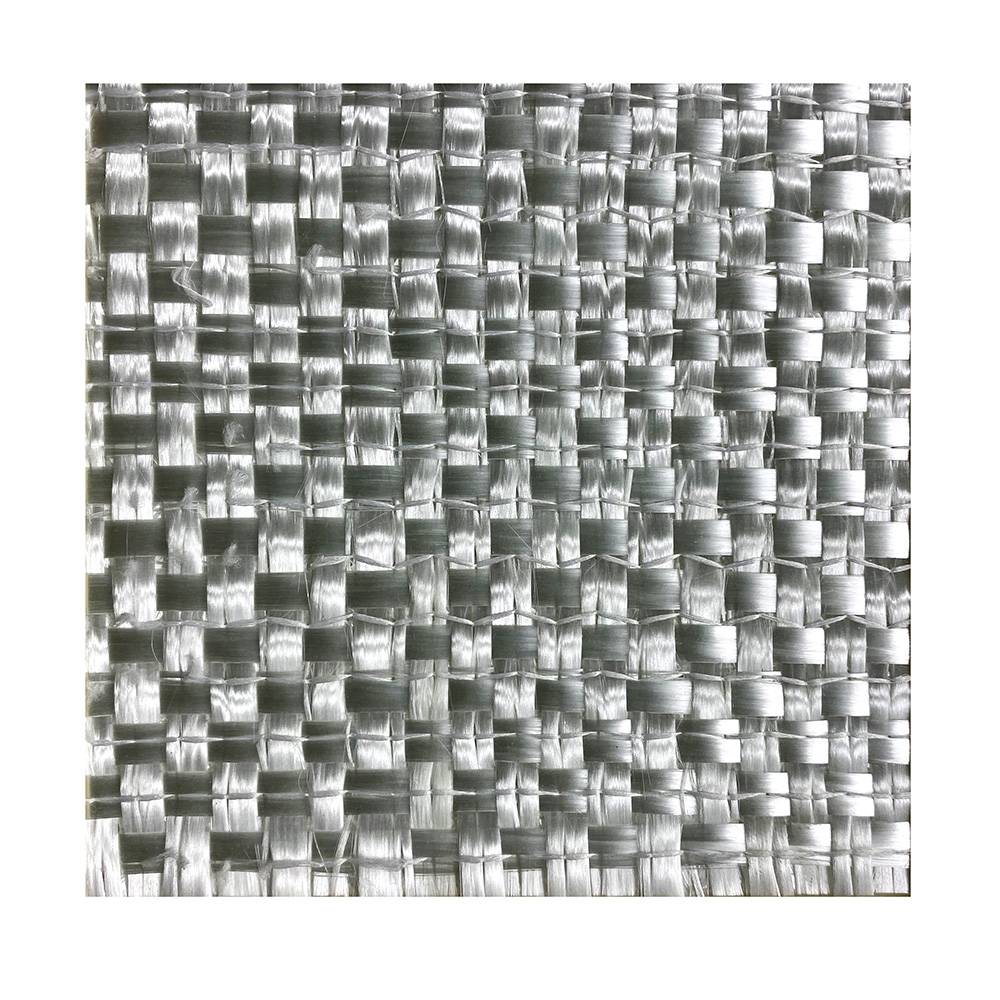

Woven Roving Combo Mat

1. Nws yog knitted nrog ob theem, fiberglass woven ntaub thiab chop lev.

2. Qhov hnyav tiag tiag yog 300-900g / m2, daim lev chop yog 50g / m2-500g / m2.

3. Qhov dav tuaj yeem ncav cuag 110 nti.

4. Kev siv tseem ceeb yog caij nkoj, cua tshuab thiab khoom siv kis las. -

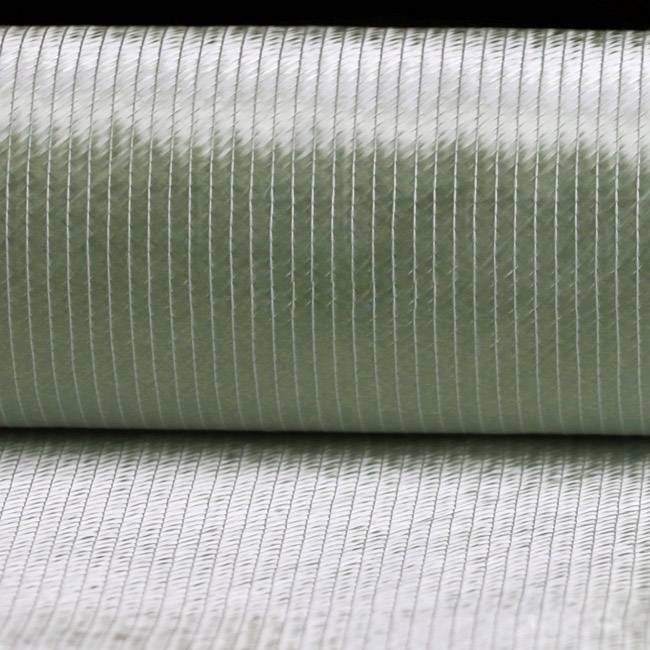

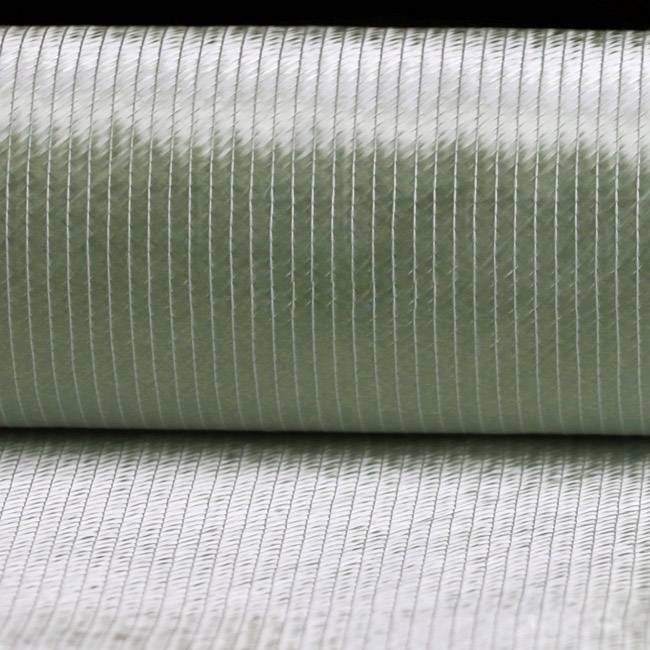

Daim lev ib sab

1.0 degree unidirectional lev thiab 90 degree unidirectional lev.

2. Qhov ceev ntawm 0 unidirectional mats yog 300g / m2-900g / m2 thiab qhov ceev ntawm 90 unidirectional mats yog 150g / m2-1200g / m2.

3. Nws yog siv los ua cov raj thiab cov hniav ntawm cov cua zog turbines. -

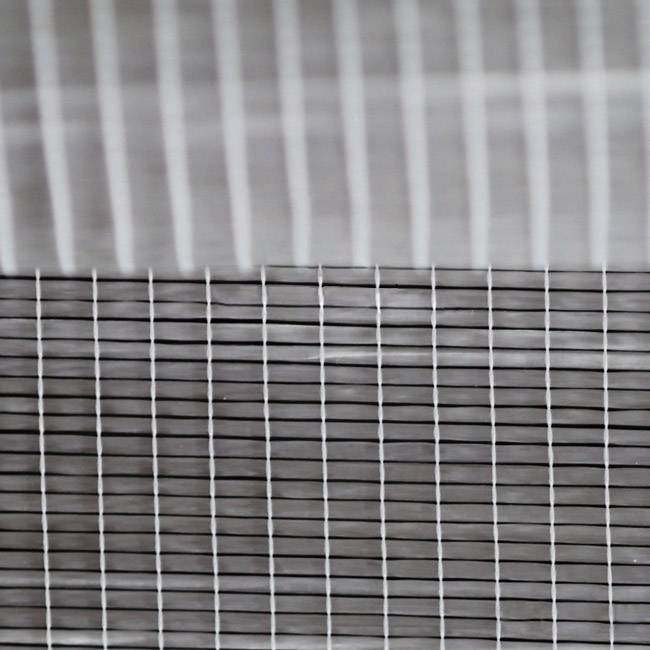

Npuag Biaxial 0°90°

1. Ob txheej ntawm roving (550g / ㎡-1250g / ㎡) raug sib dhos ntawm + 0 ° / 90 °

2. Nrog lossis tsis muaj ib txheej ntawm cov xov txiav (0g / ㎡-500g / ㎡)

3. Siv rau hauv kev tsim nkoj thiab cov khoom siv tsheb. -

Triaxial Npuag Transverse Trixial (+ 45 ° 90 ° -45 °)

1. Peb txheej ntawm cov ntaub roving tuaj yeem xaws tau, txawm li cas los xij ib txheej ntawm cov xov txiav (0g / ㎡-500g / ㎡) lossis cov ntaub ntawv sib xyaw tuaj yeem ntxiv.

2. Qhov dav tshaj plaws tuaj yeem yog 100 nti.

3. Nws yog siv rau hauv cov hniav ntawm lub zog cua turbines, kev tsim nkoj thiab kev qhia txog kev ua si.