Ua ib qho kev daws teeb meem tseem ceeb hauv kev tiv thaiv kub siab, cov ntaub fiberglass thiab cov thev naus laus zis refractory fiber txau txhawb kev txhim kho kev nyab xeeb ntawm cov khoom siv hauv kev lag luam thiab kev siv hluav taws xob zoo. Tsab xov xwm no yuav tshuaj xyuas cov yam ntxwv ntawm kev ua tau zoo ntawm ob lub thev naus laus zis no, cov xwm txheej ntawm daim ntawv thov thiab tus nqi ntawm kev tsim kho tshiab, los muab cov ntaub ntawv siv rau cov neeg siv kev lag luam.

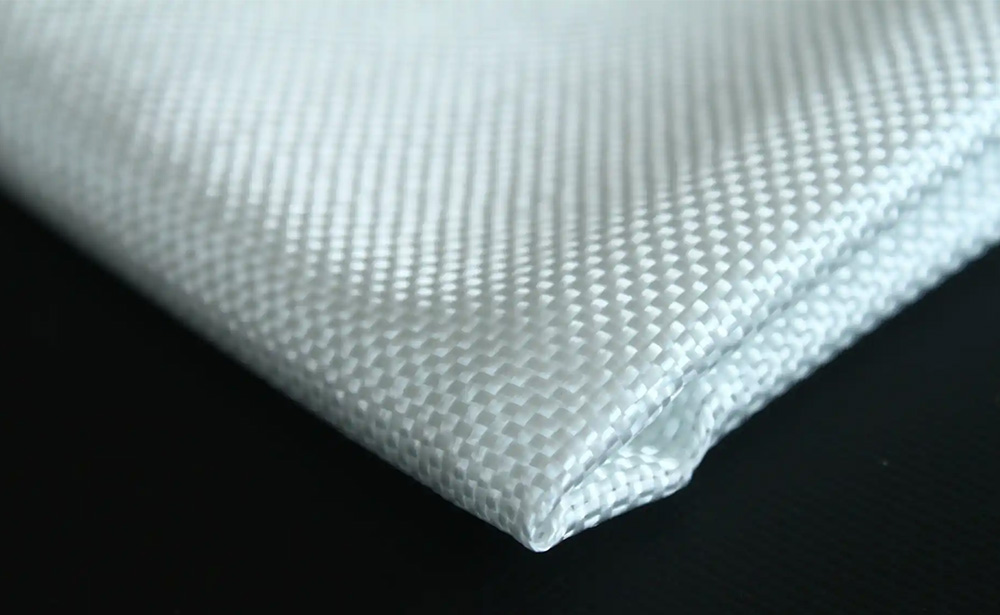

Daim ntaub fiberglass: cov khoom siv tseem ceeb rau kev tiv thaiv kub siab

Cov ntaub fiberglass raws li cov khoom siv inorganic non-metallic, los ntawm cov txheej txheem tshwj xeeb los muab nws cov kev ua tau zoo heev, kub siab, corrosion thiab complex environments ua cov khoom tiv thaiv zoo tagnrho:

1. Kev Kub Siab Tiv Thaiv

Ib txwm muajdaim ntaub fiberglasstuaj yeem tiv taus qhov kub siab tshaj 500 ° C, thiab cov khoom silica siab tuaj yeem tiv taus qhov chaw ib puag ncig siab tshaj 1000 ° C. Nws yog siv dav hauv cov khoom siv hluav taws xob metallurgical, kev rwb thaiv tsev spacecraft thiab lwm yam xwm txheej.

2. Cov Khoom Uas Tiv Thaiv Hluav Taws Thiab Rwb Thaiv Kub

Nws qhov hluav taws kub tsis kam tuaj yeem cais tawm qhov kev sib kis ntawm cov nplaim taws, thiab nws kuj muaj kev tiv thaiv rwb thaiv tsev siab (10¹²-10¹⁵Ω-cm), uas yog qhov tsim nyog rau kev tiv thaiv cov khoom siv hluav taws xob thiab kev rwb thaiv tsev ntawm cov khoom siv hluav taws xob.

3. Kev tiv thaiv corrosion thiab lub teeb yuag

Kev tiv thaiv kev puas tsuaj ntawm cov kua qaub thiab alkali ua rau nws yog thawj qhov kev xaiv rau kev tiv thaiv cov kav dej tshuaj lom neeg thiab lub tank; nrog rau qhov ceev ntawm tsuas yog 1/4 ntawm cov hlau, nws pab txhawb rau kev tsim qauv sib dua hauv kev lag luam aerospace thiab automotive.

Cov ntawv thov ib txwm muaj:

- Cov khoom siv kub siab rau kev lag luam: lub hauv paus cua sov, cov yeeb nkab kub siab rwb thaiv tsev.

- Lub zog tshiab: kev txhawb nqa lub hnub ci backplane, kev txhim kho lub zog cua.

- Kev siv tshuab hluav taws xob: 5G chaw nres tsheb hauv paus nthwv dej-pob tshab qhov chaw, kev tiv thaiv rwb thaiv tsev siab kawg.

Kev Siv Tshuab Tshuaj Txhuam Refractory Fiber: Kev Hloov Kho Tshiab ntawm Cov Khoom Siv Rau Hauv Qhov Cub Uas Muaj Cub

Kev siv tshuab txau cov fiber refractory los ntawm kev siv tshuab ntawm kev tsim kho, cov fiber thiab cov neeg sawv cev sib xyaw ncaj qha txau rau ntawm qhov chaw ntawm cov khoom siv, kev tsim cov qauv network peb-seem, ua rau kev tiv thaiv zoo dua:

1. Cov txiaj ntsig

- Kev txuag hluav taws xob thiab txo kev siv: kev ua haujlwm zoo heev, txo qhov poob cua sov ntawm lub cev cub tawg los ntawm 30% -50%, txuas lub neej ntawm lub hauv paus cub tawg ntau dua 2 zaug.

- Kev tsim kho yooj ywm: hloov kho rau cov chaw nkhaus thiab cov qauv zoo li cas, qhov tuab tuaj yeem hloov kho tau meej (10-200mm), daws qhov teeb meem ntawm cov seams tsis yooj yim ntawm cov khoom siv fiber ib txwm muaj.

- Kho sai: txhawb kev kho cov khoom siv qub online, txo lub sijhawm tsis ua haujlwm thiab txo cov nqi kho.

2. Kev tsim kho tshiab ntawm cov khoom siv

Ua ke nrog fiberglass substrate nrog tungsten carbide, alumina thiab lwm yam txheej txheem txheej txheem, nws tuaj yeem txhim kho kev hnav tsis kam thiab kev kub siab (tiv taus ntau dua 1200 ° C) kom tau raws li qhov xav tau ntawm cov hlau smelting, petrochemical reactors thiab lwm yam.

Daim Ntawv Thov Xwm Txheej:

- Cov ntaub thaiv cua sov rau kev lag luam: kev rwb thaiv tshav kub thiab kev tiv thaiv refractory rau lub cub tawg thiab lub cub tawg kho cua sov.

- Cov khoom siv hluav taws xob: txheej tiv thaiv kev poob siab thermal rau cov chav sib txuas roj turbine thiab cov kav dej boiler.

- Kev tiv thaiv ib puag ncig engineering: corrosion-resistant txheej rau cov khoom siv kho cov roj khib nyiab.

Cov ntaub ntawv thov kev sib koom ua ke: kev sib koom ua ke ntawm thev naus laus zis los tsim kom muaj txiaj ntsig tshiab

1. Kev Tiv Thaiv Sib Xyaws

Hauv cov thoob khib nyiab petrochemical,daim ntaub fiberglassyog muab tso ua txheej rwb thaiv tsev kub yooj yim, thiab tom qab ntawd cov fibers refractory raug txau kom txhim kho kev sib khi, thiab kev txuag hluav taws xob tag nrho tau nce 40%.

2. Kev Tsim Kho Tshiab Hauv Huab Cua

Ib lub tuam txhab ua dav hlau siv tshuab txau rau kev hloov kho qhov chaw ntawm cov ntaub fiberglass, uas ua rau qhov kub ntawm lub cav chav tsev rwb thaiv tsev kub nce mus txog 1300 ° C thiab txo qhov hnyav los ntawm 15%.

Kev lag luam dynamics thiab yav tom ntej sib txawv

1. Kev Txhim Kho Peev Xwm thiab Kev Siv Tshuab

Sichuan Fiberglass Group thiab lwm lub tuam txhab lag luam kom nrawm dua qhov kev nthuav dav ntawm lub peev xwm tsim khoom, hluav taws xob fiberglass yarn muaj peev xwm ntawm 30,000 tons hauv xyoo 2025, thiab kev tshawb fawb thiab kev txhim kho ntawm cov khoom dielectric qis, kev hloov pauv kub siab, kom hloov kho rau qhov kev thov rau kev siv tshuab txau.

2. Cov Qauv Tsim Khoom Ntsuab

Kev siv tshuab txau cov fiber refractory txo cov khoom pov tseg los ntawm 50% thiab cov pa roj carbon los ntawm 20%, uas yog raws li lub hom phiaj thoob ntiaj teb carbon neutral.

3. Kev Txhim Kho Kev Txawj Ntse

Ua ke nrog AI algorithms los ua kom zoo dua cov txheej txheem txau, nws paub txog kev tswj hwm ntse ntawm kev sib npaug thiab tuab ntawm txheej, thiab txhawb kev tiv thaiv kev lag luam kom raug.

Xaus lus

Kev siv synergistic ntawmdaim ntaub fiberglassthiab cov thev naus laus zis refractory fiber spraying tab tom hloov kho cov ciam teb ntawm kev tiv thaiv kub siab hauv kev lag luam. Txij li kev tsim khoom ib txwm mus rau kev siv tshuab tshiab, ob qho tib si muab cov kev daws teeb meem zoo thiab ruaj khov rau lub zog, metallurgy, aerospace thiab lwm yam kev lag luam los ntawm kev ua tau zoo sib xws thiab kev tsim kho tshiab.

Lub sijhawm tshaj tawm: Lub Peb Hlis-17-2025