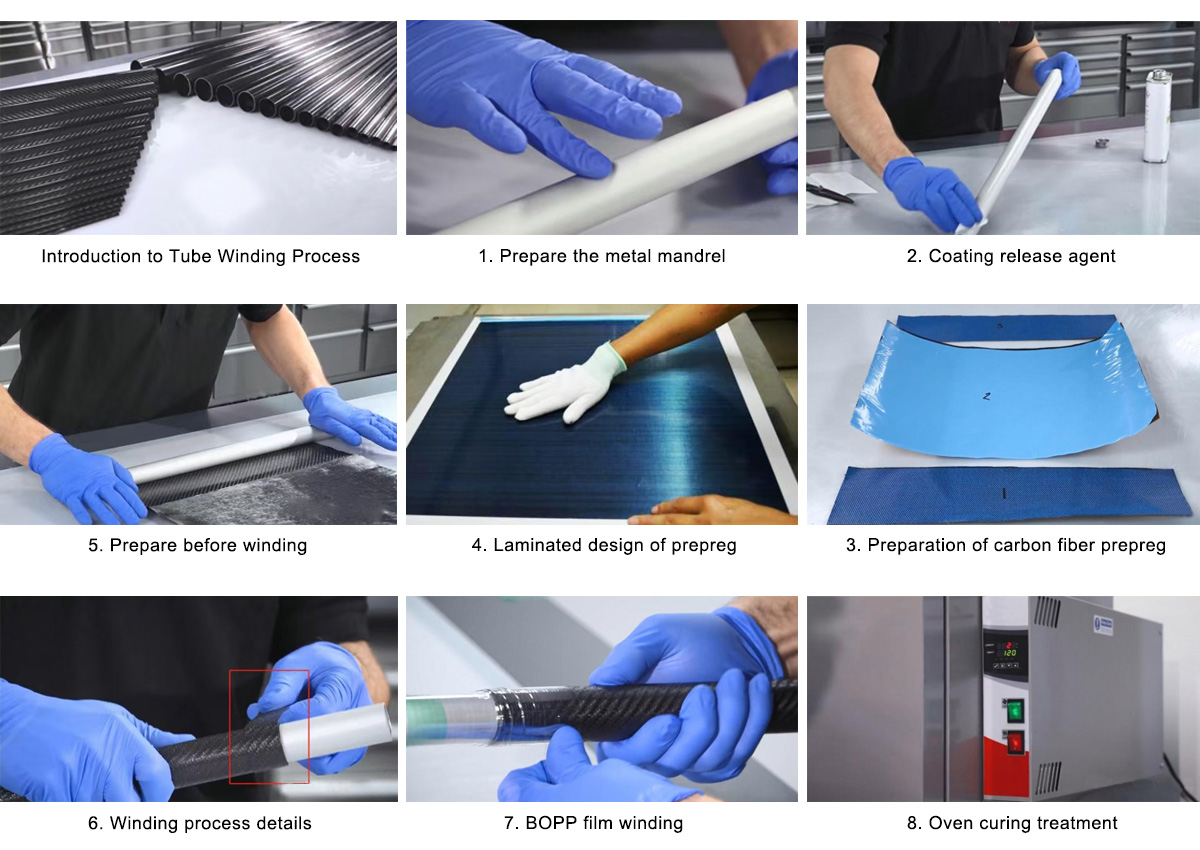

1. Kev Taw Qhia Txog Cov Txheej Txheem Winding Raj

Los ntawm cov lus qhia no, koj yuav kawm paub siv cov txheej txheem winding raj los tsim cov qauv tubular siv cov carbon fiber prepregs ntawm lub tshuab winding raj, yog li ua rau muaj zog siab.cov raj carbon fiberCov txheej txheem no feem ntau siv los ntawm cov chaw tsim khoom siv sib xyaw.

Yog tias koj xav tsim cov raj uas muaj sab sib luag lossis cov taper tas mus li, cov txheej txheem winding raj yog qhov kev xaiv zoo tshaj plaws. Txhua yam koj xav tau yog lub mandrel hlau ntawm qhov loj me thiab lub qhov cub los tsim cov raj carbon fiber tshwj xeeb uas tsim rau koj cov kev xav tau tshwj xeeb.

Rau cov raj carbon fiber uas muaj cov duab nyuaj, xws li cov handlebars lossis cov qauv raj uas nyuaj dua xws li cov forks lossis cov thav tsheb kauj vab, kev siv tshuab split-mold yog txoj kev nyiam tshaj plaws. Tam sim no peb yuav qhia txog yuav siv cov tshuab split-mold li cas los tsim cov raj carbon fiber no.

2. Kev Ua thiab Kev Npaj Cov Hlau Mandrels

- Qhov Tseem Ceeb ntawm Cov Hlau Mandrels

Ua ntej pib txoj kev winding lub raj, thawj kauj ruam yog npaj cov hlau mandrels. Cov hlau mandrels yuav tsum phim lub cheeb tsam sab hauv ntawm cov raj, thiab lawv qhov du thiab kev kho ua ntej yog qhov tseem ceeb. Tsis tas li ntawd, cov hlau mandrels yuav tsum tau ua ntej kev kho kom zoo, xws li kev ntxuav thiab siv cov tshuaj tso tawm, kom yooj yim rau cov txheej txheem demolding tom qab.

Thaum lub sijhawm ua haujlwm ntawm lub raj xa dej, lub mandrel hlau ua lub luag haujlwm tseem ceeb vim nws yuav tsum txhawb nqacarbon fiber prepregkom ntseeg tau tias qhov winding du. Yog li ntawd, npaj qhov loj me ntawm cov hlau mandrel ua ntej yog qhov tseem ceeb. Txij li thaum cov carbon fiber yuav raug qhwv ncig lub ntsej muag sab nraud ntawm lub mandrel, lub cheeb sab nraud ntawm lub mandrel yuav tsum phim lub cheeb sab hauv ntawm cov carbon fiber raj uas yuav tsim tawm.

- Siv cov neeg sawv cev tso tawm

Cov tshuaj tso tawm txo qhov kev sib txhuam thiab ua kom du thiab du thaum rhuav cov pwm; yuav tsum tau siv rau ntawm qhov chaw ntawm lub mandrel. Tom qab npaj lub mandrel hlau lawm, kauj ruam tom ntej yog siv cov tshuaj tso tawm. Cov tshuaj tso tawm feem ntau siv suav nrog roj silicone thiab paraffin, uas txo qhov kev sib txhuam ntawm cov carbon fiber thiab lub mandrel hlau.

Ntawm lub mandrel hlau uas tau npaj tseg, peb yuav tsum xyuas kom meej tias nws huv si thiab qhov chaw du li sai tau kom yooj yim rau kev rhuav cov khoom. Tom qab ntawd, cov tshuaj tso tawm yuav tsum tau siv sib npaug zos rau ntawm qhov chaw ntawm lub mandrel.

3. Kev npaj cov roj carbon fiber prepreg

- Cov hom thiab cov txiaj ntsig ntawm prepreg

Tsuas yog cov carbon fiber prepregs ua tau raws li qhov yuav tsum tau ua rau qhov tseeb ntawm winding thiab yooj yim ntawm kev tuav. Txawm hais tias lwm hom khoom siv reinforcing, xws li epoxy-impregnated qhuav fabrics, tuaj yeem siv tau rau hauv cov txheej txheem winding, hauv kev xyaum, tsuas yog carbon fiber prepregs tuaj yeem ua tau raws li qhov yuav tsum tau ua rau qhov tseeb thiab yooj yim ntawm kev tuav hauv cov txheej txheem no.

Hauv zaj lus qhia no, peb siv ib txoj kev tshwj xeeb prepreg layering los txhim kho kev ua haujlwm ntawm cov raj.

- Kev Tsim Qauv Prepreg Layup

Ib txheej ntawm cov ntaub prepreg raug muab tso rau sab hauv ntawm lub raj, ua raws li ntau txheej ntawm unidirectional prepreg, thiab thaum kawg lwm txheej ntawm woven prepreg raug siv rau sab nraud ntawm lub raj. Qhov kev tsim layup no siv tag nrho cov txiaj ntsig ntawm cov fiber orientation ntawm woven prepreg ntawm 0° thiab 90° axes, ua kom lub raj ua tau zoo dua. Feem ntau ntawm unidirectional prepregs muab tso rau ntawm 0° axis muab kev ruaj khov zoo rau lub raj.

4. Cov txheej txheem ntws ntawm cov yeeb nkab

- Kev npaj ua ntej winding

Tom qab ua tiav qhov kev tsim qauv prepreg, cov txheej txheem yuav mus rau cov txheej txheem winding yeeb nkab. Kev ua Prepreg suav nrog kev tshem tawm cov yeeb yaj kiab PE thiab cov ntawv tso tawm, thiab khaws cov chaw sib tshooj kom tsim nyog. Cov kauj ruam no yog qhov tseem ceeb rau kev ua kom ntseeg tau tias cov txheej txheem winding tom ntej no ua tiav.

- Cov ntsiab lus ntawm cov txheej txheem winding

Thaum lub sijhawm ua cov txheej txheem winding, nws yog ib qho tseem ceeb kom ntseeg tau tias cov prepregs winding du, nrog rau lub hlau core ncej muab tso ruaj khov thiab siv zog sib npaug. Lub hlau core ncej yuav tsum tau muab tso ruaj khov rau ntawm ntug ntawm thawj txheej ntawm prepregs, kom ntseeg tau tias muaj kev siv zog sib npaug.

Thaum lub sijhawm winding, ntxiv prepregs tuaj yeem raug qhwv rau ntawm qhov kawg kom pab tshem tawm cov khoom thaum lub sijhawm demolding.

- BOPP Zaj Duab Xis Qhwv

Ntxiv rau qhov prepreg, BOPP zaj duab xis kuj tseem siv tau rau kev qhwv. BOPP zaj duab xis ua rau muaj kev sib sau ua ke, tiv thaiv, thiab kaw lub prepreg. Thaum siv BOPP zaj duab xis qhwv, nws yog ib qho tseem ceeb kom ntseeg tau tias muaj kev sib tshooj txaus ntawm cov kab xev.

5. Cov Txheej Txheem Kho Qhov Cub

- Kub thiab Lub Sijhawm Kho

Tom qab qhwv cov khoom siv carbon fiber reinforced prepreg kom nruj, nws raug xa mus rau qhov cub kom kho. Kev tswj qhov kub thiab txias yog qhov tseem ceeb thaum lub sijhawm kho hauv qhov cub, vim tias cov prepregs sib txawv muaj cov xwm txheej kho sib txawv. Cov kauj ruam no yog qhov tseem ceeb rau kev ua kom cov khoom ruaj khov thiab txhim kho kev ua tau zoo.

Los ntawm qhov kub siab heev hauv qhov cub, qhovcov roj carbon fiberthiab cov resin matrix teb tag nrho, tsim cov khoom siv sib xyaw ua ke.

6. Kev Tshem Tawm thiab Kev Ua Haujlwm

Tom qab tshem daim zaj duab xis BOPP tawm lawm, cov khoom uas kho tau tuaj yeem tshem tawm. Daim zaj duab xis BOPP tuaj yeem tshem tawm tom qab kho tau. Yog tias tsim nyog, qhov tsos tuaj yeem txhim kho los ntawm kev xuab zeb thiab pleev xim. Rau kev txhim kho kom zoo nkauj ntxiv, cov txheej txheem tiav ntxiv xws li xuab zeb thiab pleev xim tuaj yeem ua tau.

Lub sijhawm tshaj tawm: Lub Yim Hli-11-2025