Fiberglass Chopped Strands suav nrogCov Strands Txiav Rau BMC, Cov Strands Txiav Rau Thermoplastics, Cov Strands Txiav Uas Ntub Dej, Cov Strands Txiav Uas Tiv Thaiv Alkali (ZrO2 14.5% / 16.7%).

1). Cov Strands Chopped Rau BMC

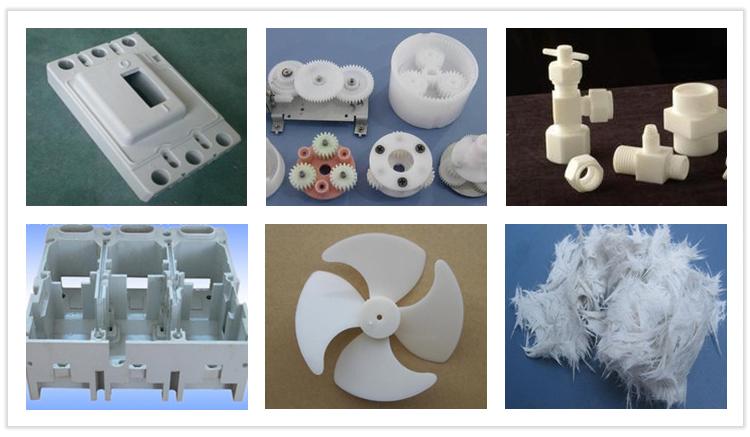

Cov Strands Chopped rau BMC yog sib xws nrog unsaturated polyester, epoxy resin thiab phenolic resins.

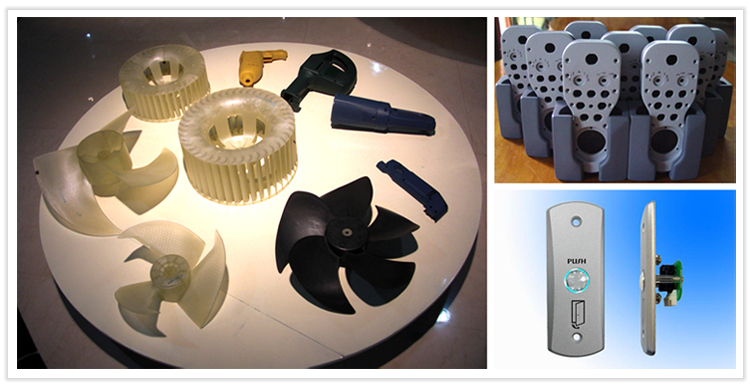

Cov ntawv thov siv kawg suav nrog kev thauj mus los, kev tsim kho & kev tsim kho, hluav taws xob & hluav taws xob, tshuab, thiab kev lag luam lub teeb.

2). Cov Strands Txiav Rau Thermoplastics

Cov Khoom Siv Thermoplastic Uas Tau Txiav Rau Cov Khoom Siv Thermoplastic yog ua raws li tus neeg sawv cev silane coupling thiab cov qauv tsim tshwj xeeb, sib xws nrog PA, PBT / PET, PP, AS / ABS, PC, PPS / PPO, POM, LCP;

E-Iav Chopped Stands rau thermoplastic paub txog kev ua tiav zoo heev, kev ntws zoo dua thiab cov khoom ua tiav, xa cov khoom siv kho tshuab zoo heev thiab qhov zoo ntawm qhov chaw rau nws cov khoom tiav.

3.) Cov xov txiav ntub dej

Cov xov uas ntub dej sib xyaw ua ke nrog cov polyester tsis muaj roj, epoxy thiab phenolic resins thiab gypsum.

Cov xov uas ntub dej muaj cov dej noo nruab nrab thiab xa cov dej ntws zoo heev, suav nrog kev sib kis hauv dej thiab hauv gypsum.

4.) Cov xov txiav uas tiv taus alkali (ZrO2 14.5% / 16.7%)

Kuv).Ua ntej sib tov Cov xov txiav uas tiv taus alkali–(ZrO2 14.5% / 16.7%)

Premix chopped strands yog cov iav fiber ntau uas tiv taus alkali rau kev siv dav dav uas npaj rau kev sib xyaw ua ntej nrog lwm cov ntaub ntawv thiab yog tsim los ntawm kev siv tamping casting lossis lwm cov txheej txheem hauv ib qho GRC molded.

Txawm tias nyob rau hauv cov xwm txheej siab kuj yooj yim heev rau kev sib koom ua ke, thiab tom qab sib tov ua ke zoo. Rau kev tsim cov khoom siv GRC txheem xws li cov kav dej lossis cov thawv ntsuas, lossis cov chaw tsim kho xws li cov laug cam sib faib, zirconia cov ntsiab lus ntawm 16.7% chopped yarn ntau lawm cov khoom ntawm lub zog lig ntawm kev ua tau zoo dua

II). TEX qisCov xov txiav uas tiv taus alkali–(ZrO2 14.5% / 16.7%)

Cov xov txiav Low Tex yog cov xov txiav iav fiber ntau uas muaj Intergrity siab, low tex, alkali-resistant, siv rau kev molding GRC Cheebtsam hauv cov txheej txheem sib tov qhuav lossis lwm cov txheej txheem ua ntej. Nws kuj tseem siv tau rau kev tsim cov khoom ua ntej hauv cov khoom GRC txheem.

Lub tshuab ua kom ntub dej tshwj xeeb ua rau nws yooj yim sib tov thiab tswj tau qhov zoo thaum sib tov, tiv thaiv kev hnav thiab tswj cov khoom sib xyaw thaum sib tov nrog cov ntaub qhuav. Cov xov uas muaj qhov ceev tsawg ib txoj xov tuaj yeem ua rau thaj chaw tshwj xeeb nce ntxiv nrog kev koom tes tsawg, thiab yog li ua rau muaj kev txhim kho zoo dua. Cov khoom no tsim nyog rau kev npaj cov mortar thiab cov xim sib tov ua ntej.

III). Dej tau tawg ua tej daim me me Cov xov txiav uas tiv taus alkali–(ZrO2 14.5% / 16.7%)

Cov dej faib cov xov txiav yog lub hom phiaj tshwj xeeb alkali-resistant iav fiber txiav strand, siv rau kev sib tov nrog cement thiab lwm yam khoom siv uas xav tau kev sib kis siab. Tshwj xeeb tshaj yog rau cov av nkos tshwj xeeb ntawm kev hnav khaub ncaws lossis rau cov kua dej thiab lwm yam kev lag luam tshwj xeeb.

Cov khoom siv ntsuas qhov loj me yog cov dej-dispersible thiab, thaum sib xyaw nrog dej, tuaj yeem dispersed txaus rau hauv monofilaments. Siv rau hauv kev pleev xim thiab kho cov pob zeb sib xyaw, thiab los ntawm cov txheej txheem tshwj xeeb los tsim cov khoom GRC txheem.

Lub sijhawm tshaj tawm: Lub Peb Hlis-03-2021