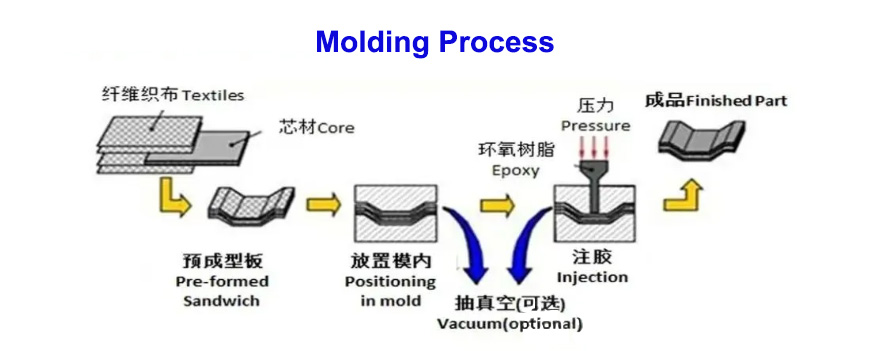

Cov txheej txheem molding yog ib qho nyiaj ntawm prepreg rau hauv cov pwm hlau qhov ntawm cov pwm, siv cov xovxwm nrog lub cua sov los tsim ib qho kub thiab siab kom cov prepreg hauv cov pwm qhov yog softened los ntawm cua sov, siab ntws, puv ntawm ntws, puv nrog cov pwm qhov molding thiab kho cov khoom ntawm ib txoj kev txheej txheem.

Lubtxheej txheem moldingyog tus cwj pwm los ntawm qhov xav tau cua sov hauv cov txheej txheem molding, lub hom phiaj ntawm cua sov yog ua kom cov prepreg resin softening ntws, puv nrog pwm qhov, thiab ua kom cov tshuaj kho sai dua ntawm cov khoom siv resin matrix. Thaum lub sijhawm sau cov pwm qhov nrog prepreg, tsis yog tsuas yog cov resin matrix ntws xwb, tab sis kuj yog cov khoom siv reinforcing, thiabcov roj hmabcov matrix thiab cov fibers reinforcing sau txhua qhov ntawm cov pwm qhov tib lub sijhawm.

Tsuas yog qhov viscosity ntawm cov resin matrix loj heev, thiab qhov sib txuas muaj zog txaus kom ntws nrog cov fibers reinforcing, yog li cov txheej txheem molding xav tau lub siab molding ntau dua. Qhov no xav tau cov pwm hlau nrog lub zog siab, qhov tseeb siab, thiab kev tiv thaiv corrosion, thiab nws xav tau kev siv cov xovxwm kub tshwj xeeb los tswj qhov kub ntawm cov pwm kho, siab, tuav lub sijhawm, thiab lwm yam txheej txheem.

Txoj kev molding muaj kev ua haujlwm siab, qhov loj ntawm cov khoom raug, thiab qhov chaw tiav, tshwj xeeb tshaj yog rau cov qauv nyuaj ntawm cov khoom sib xyaw feem ntau tuaj yeem pwm ib zaug, thiab yuav tsis ua puas rau kev ua haujlwm ntawm cov khoom sib xyaw. Nws qhov tsis zoo tseem ceeb yog tias kev tsim pwm thiab kev tsim khoom nyuaj dua, thiab kev nqis peev thawj zaug loj dua. Txawm hais tias cov txheej txheem molding muaj qhov tsis zoo saum toj no, cov pwmtxheej txheem moldingtseem nyob hauv txoj haujlwm tseem ceeb hauv cov txheej txheem molding khoom sib xyaw.

1. Kev Npaj

Ua ib txoj haujlwm zoo ntawm kev npaj ua ntej, molding tooling pwm, nrog rau qhov cub tawg sim daim ntawm kev txhawb nqa ua haujlwm, thiab ntxuav cov pwm hauv qhov kev siv zaum kawg ntawm cov residual residual residues, thiab cov khib nyiab, kom cov pwm huv si thiab du.

2. Kev txiav thiab tso cov prepregs

Yuav ua rau cov khoom siv carbon fiber raw khoom npaj txhij, prepreg tom qab dhau qhov kev tshuaj xyuas, xam thaj tsam ntawm cov khoom siv raw, cov ntaub ntawv, tus lej ntawm cov ntawv, cov khoom siv raw txheej los ntawm txheej ntawm cov tshuaj tsw qab ntxiv, tib lub sijhawm ntawm qhov sib tshooj ntawm cov khoom siv rau qhov ua ntej-siab, nias rau hauv cov duab ntawm ib txwm muaj, qhov zoo ntawm qee qhov lej ntawm cov chaw ntom ntom.

3. Kev pwm thiab kev kho

Muab cov khoom siv raw uas tau muab sib dhos ua ke rau hauv pwm, thiab tib lub sijhawm hauv lub hnab yas sab hauv, kaw lub pwm, tag nrho rau hauv lub tshuab molding, lub hnab yas sab hauv ntxiv rau qee qhov siab tas li, qhov kub tas li, teem sijhawm tas li kom nws kho.

4. Txias thiab rhuav tshem

Tom qab ib lub sijhawm ntawm lub sijhawm ntawm kev siab sab nraum lub pwm thawj zaug txias paub rau ib lub sijhawm, thiab tom qab ntawd qhib lub pwm, demolding sab nraum lub qhov muag los ntxuav cov pwm tooling.

5. Ua molding

Tom qab demolding cov khoom yuav tsum tau ntxuav, nrog txhuam hlau lossis txhuam tooj liab kom khawb cov yas seem, thiab tshuab nrog cua compressed, cov khoom molded yog polished, kom qhov chaw du thiab huv.

6. Kev sim tsis puas tsuaj thiab kev tshuaj xyuas zaum kawg

Kev sim tsis ua puas tsuaj thiab kev tshuaj xyuas zaum kawg ntawm cov khoom raug ua raws li qhov yuav tsum tau ua ntawm cov ntaub ntawv tsim.

Txij li thaum yug loscov khoom sib xyaw ua los ntawm cov roj carbon fiber, ib txwm txwv los ntawm tus nqi tsim khoom thiab kev tsim khoom ntau lawm, tsis tau siv rau hauv ntau ntau. Qhov kev txiav txim siab ntawm cov nqi tsim khoom carbon fiber thiab kev tsim khoom yog cov txheej txheem molding, cov txheej txheem molding khoom siv carbon fiber ntau muaj ntau, xws li RTM, VARI, lub tank kub nias, qhov cub kho prepreg (OOA), thiab lwm yam, tab sis muaj ob lub bottlenecks: 1, lub sijhawm molding ntev; 2, tus nqi kim heev (piv rau hlau thiab yas). Prepreg molding txheej txheem, ua ib hom molding txheej txheem, tuaj yeem paub txog kev tsim khoom ntau thiab txo tus nqi tsim khoom, uas yog siv ntau dua thiab dav dua.

Lub sijhawm tshaj tawm: Lub Ib Hlis-09-2025