Cov yam ntxwv ntawm cov khoom

Lub zog siab thiab kev ua haujlwm siab, kev tiv thaiv corrosion, kev poob siab tsis kam, kev cuam tshuam tsis kam, kev tsim kho yooj yim, kev ua haujlwm zoo, thiab lwm yam.

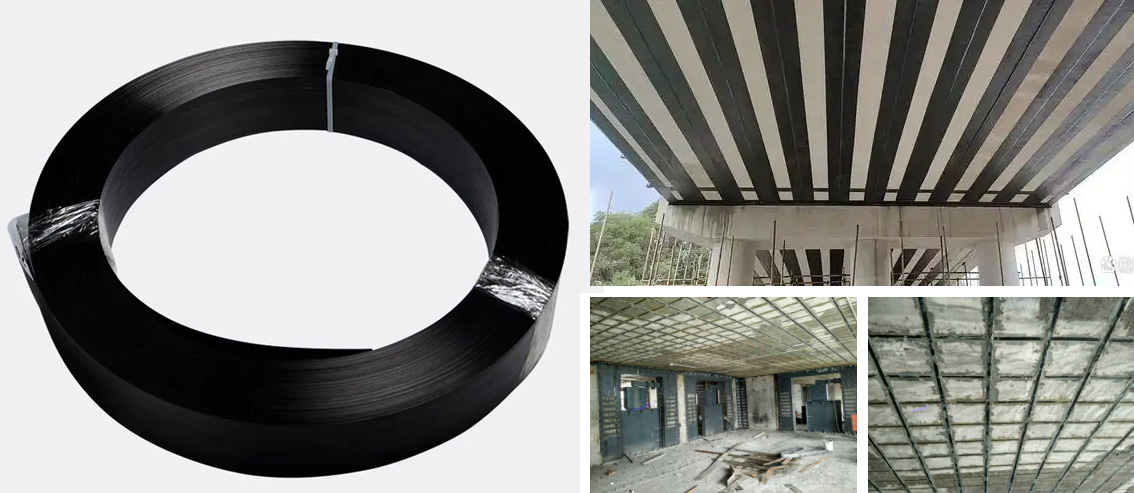

Scope ntawm daim ntawv thov

Kev khoov ntawm cov nqaj hlau ua los ntawm cov pob zeb, kev txhawb nqa shear, cov pob zeb hauv pem teb, kev txhawb nqa ntawm tus choj deck, pob zeb ua vaj tse, phab ntsa cib masonry, kev txhawb nqa ntawm phab ntsa txiab, qhov av, pas dej ua ke thiab lwm yam kev txhawb nqa.

Kev khaws cia thiab kev thauj mus los

Yuav tsum khaws cia rau qhov chaw qhuav, txias thiab muaj cua nkag, tsis txhob cia nag los yog hnub raug.

Kev thauj mus los thiab kev khaws cia yuav tsum tsis txhob raug extrusion, yog li ntawd kom tsis txhob muaj kev puas tsuaj raucov roj carbon fiber.

Cov lus qhia txog kev tsim kho ntawm Vibranium phaj reinforcement

1. Kev kho cov pob zeb ua vaj tse

(1) Nrhiav thiab tso cov kab raws li cov duab kos hauv qhov chaw uas tau muab nplaum.

(2) Cov pob zeb ua vaj tse yuav tsum tau chiseled deb ntawm cov txheej whitewash, roj, av, thiab lwm yam, thiab tom qab ntawd siv lub tshuab sib tsoo lub kaum sab xis los sib tsoo cov txheej saum npoo 1 ~ 2 hli tuab thiab tshuab kom huv si nrog lub tshuab cua kom pom qhov huv si, tiaj tus, thiab cov qauv khov kho, yog tias muaj cov kab nrib pleb hauv cov pob zeb ua vaj tse, nws yuav tsum xub xaiv qhov loj ntawm cov kab nrib pleb los yog grouting kua nplaum grouting thiab tom qab ntawd reinforcement.

2, Kev kho mob kom sib npaug

Yog tias muaj qhov tsis zoo, qhov thiab qhov siab ntawm cov pob qij txha ntawm cov qauv ntawm qhov chaw uas tau muab tshuaj txhuam, siv cov kua nplaum leveling los khawb thiab sau qhov kho kom paub tseeb tias tsis muaj qhov sib txawv ntawm qhov siab ntawm cov pob qij txha, qhov tsis zoo thiab qhov av du thiab du. Cov kua nplaum leveling kho thiab tom qab ntawd muab cov roj carbon fiber board nplaum.

3. Muab tshuaj txhuamcov roj carbon fiber board

(1) Txiav cov carbon fiber board raws li qhov loj me uas tus qauv tsim xav tau.

(2) Cov khoom siv nplaum A thiab B raws li qhov sib piv ntawm 2: 1, siv lub tshuab sib tov, lub sijhawm sib tov yog li 2 ~ 3 feeb, sib tov kom sib npaug, thiab tiv thaiv cov hmoov av tsis huv. Cov khoom siv nplaum ib zaug yuav tsum tsis txhob ntau dhau, kom ntseeg tau tias qhov kev teeb tsa tiav hauv 30 feeb (25 ℃).

(3) Qhov saum npoo ntawm cov carbon fiber board yuav tsum tau so kom huv si, siv cov yas scraper yuav coated nrog cov nplaum rau ntawm cov carbon fiber board, cov nplaum tuab ntawm 1-3 hli (carbon fiber board nruab nrab ntawm 3 hli), yog nruab nrab ntawm cov tuab ntawm cov nyias nyias, qhov nruab nrab tuab ntawm 2 hli.

(4) Muab cov carbon fiber board tso rau hauv lub hauv paus pob zeb ua kom muaj zog, nrog rau cov roj hmab roller sib npaug zos thov kom muaj zog txaus, kom cov nplaum ntawm ob sab ntawm qhov dej ntws, kom ntseeg tau tias tsis muaj qhov khoob, kom ntseeg tau tias cov carbon fiber board thiab lub hauv paus pob zeb ncaj qha tsawg kawg 2 hli tuab ntawm cov nplaum.

(5) Tshem tawm cov khoom nplaum ntau dhau nyob ib puag ncig ntug, siv cov ntoo lossis cov ncej hlau los txhawb thiab kho cov carbon fiber board, siv lub zog kom raug, thiab tshem tawm cov kev txhawb nqa tom qab cov nplaum ntawm cov qauv kho tau kho. Thaum ntau cov carbon fiber boards raug lo rau hauv qhov sib luag, qhov sib txawv ntawm ob lub boards tsis tsawg dua 5 hli.

(6) ob txheej ntawm cov carbon fiber board yuav tsum tau muab tshuaj txhuam tas mus li, txheej hauv qab ntawm cov carbon fiber board ntawm ob sab yuav tsum tau so kom huv, xws li tsis tuaj yeem muab tshuaj txhuam tam sim ntawd thiab tom qab ntawd qhib cov tshuaj txhuam ua ntej txheej hauv qab ntawm cov carbon fiber board yuav tsum tau rov ua haujlwm ntxuav. Yog tias cov khoom siv txhawb nqa xav tau ua kev tiv thaiv txheej, koj tuaj yeem txhuam cov txheej tiv thaiv txheej tom qab kho cov tshuaj pleev.

Kev Ceev Faj Txog Kev Tsim Kho

1. Thaum qhov kub qis dua 5 ℃, qhov av noo RH> 85%, cov dej ntawm qhov chaw ua vaj tse siab dua 4%, thiab muaj qhov ua tau ntawm cov dej noo, kev tsim kho yuav tsum tsis txhob ua yam tsis muaj kev ntsuas zoo. Yog tias cov xwm txheej tsim kho tsis tuaj yeem ua tiav, nws yog qhov tsim nyog los siv txoj kev cua sov hauv zos ntawm qhov chaw ua haujlwm kom ua tiav qhov kub thiab txias, av noo thiab cov dej noo thiab lwm yam xwm txheej xav tau ua ntej kev tsim kho, qhov kub ntawm kev tsim kho ntawm 5 ℃ -35 ℃ yog qhov tsim nyog.

2. Vim tias cov roj carbon fiber yog ib qho khoom siv hluav taws xob zoo, nws yuav tsum khaws cia kom deb ntawm lub zog fais fab.

3. Cov roj hmab siv rau kev tsim kho yuav tsum khaws cia kom deb ntawm hluav taws thiab tshav ntuj ncaj qha, thiab cov roj hmab tsis siv yuav tsum tau kaw kom ruaj.

4. Cov neeg ua haujlwm tsim kho thiab tshuaj xyuas yuav tsum hnav khaub ncaws tiv thaiv, lub kaus mom kev nyab xeeb, lub ntsej muag lub ntsej muag, hnab looj tes, thiab tsom iav tiv thaiv.

5. Thaum cov tshuaj nplaum lo rau ntawm daim tawv nqaij, yuav tsum tau yaug nrog xab npum thiab dej tam sim ntawd, muab dej txau rau hauv qhov muag thiab kho mob raws sijhawm. 6, txhua qhov kev tsim kho tiav lawm, kev txuag ntuj tsim hauv 24 teev kom ntseeg tau tias tsis muaj kev cuam tshuam sab nraud thiab lwm yam kev cuam tshuam.

7. Txhua txoj kev ua thiab tom qab ua tiav, yuav tsum ua cov kauj ruam kom tsim nyog kom tsis muaj kuab paug lossis dej nag nkag. 8. Kev teeb tsa qhov chaw ua haujlwm ntawm cov nplaum yuav tsum tau khaws cia kom muaj cua nkag zoo.

9. vim yog kev sib txuas ntawmcov roj carbon fiber boardmuaj kev ntxhov siab heev, thaum tso tawm cov carbon fiber board xav tau 2-3 tus neeg nrog kev tso tawm ntawm lub yob, kom tiv thaiv cov carbon fiber board popping qhib raug mob.

10. Cov txheej txheem ua cov phaj carbon fiber yuav tsum yog lub teeb, txwv tsis pub cov khoom nyuaj thiab tib neeg nqis tes ua.

11. Kev tsim kho ntsib qhov kub poob qis sai sai, cov nplaum nplaum yuav zoo li loj heev, koj tuaj yeem siv cov kev ntsuas cua sov, xws li teeb tungsten iodine, lub cub hluav taws xob lossis cov dej da dej thiab lwm txoj hauv kev los ua kom qhov kub ntawm cov kua nplaum ua ntej siv kom preheat rau 20 ℃ -40 ℃.

Lub sijhawm tshaj tawm: Plaub Hlis-27-2025