Qhov zoo ntawm FRP pwm yog ncaj qha cuam tshuam nrog kev ua tau zoo ntawm cov khoom, tshwj xeeb tshaj yog hais txog qhov deformation tus nqi, durability, thiab lwm yam, uas yuav tsum tau ua ntej. Yog tias koj tsis paub yuav ua li cas thiaj paub qhov zoo ntawm cov pwm, thov nyeem qee cov lus qhia hauv tsab xov xwm no.

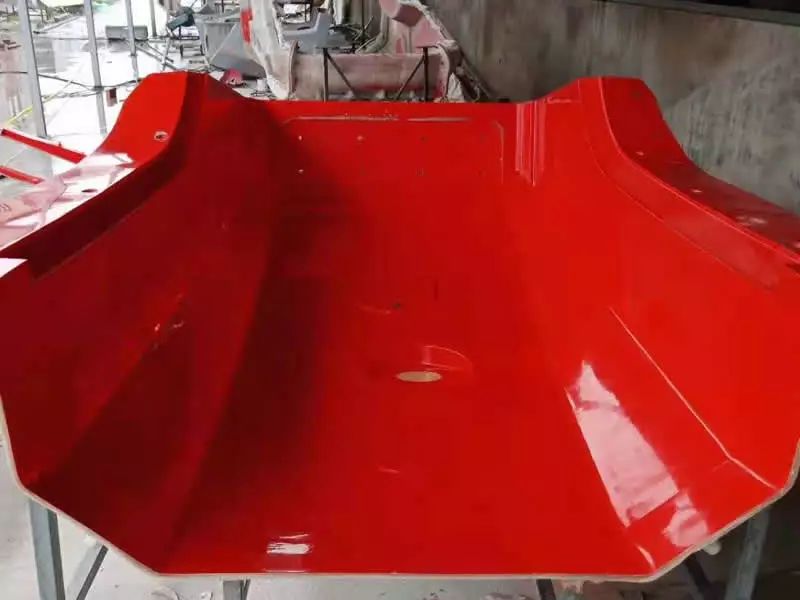

1. Kev tshuaj xyuas qhov chaw ntawm cov pwm yog ua tiav thaum nws tuaj txog, thiab nws yog qhov yuav tsum tau ua kom tsis muaj cov qauv ntaub pom ntawm qhov chaw;

2. Lub thickness ntawm lub pwm gel txheej yog ntau dua lossis sib npaug rau 0.8 hli, thiab lub thickness ntawm lub tsho gel yog lub thickness ntawm lub tsho gel tom qab kho thiab molding, tsis yog lub thickness ntawm cov zaj duab xis ntub;

3. Yuav tsum tsis txhob muaj cov roj hmab tso rau ntawm qhov chaw ntawm lub ces kaum ntawm pwm.

4. Lub cev tseem ceeb ntawm cov pwm, uas yog, qhov kub ntawm lub cev hloov pauv ntawm FRP laminate, raws li 2001 resin parameter ≥110 ℃.

5. Qhov ci ntsa iab thiab qhov tiaj tiaj ntawm qhov chaw ntawm lub tsho gel yog qhov yuav tsum tau ua kom ncav cuag qhov chaw A-level. Rau lub dav hlau kab rov tav, lub silhouette tuaj yeem pom tseeb yam tsis muaj kev hloov pauv.

6. Qhov yuav tsum tau ua kom tawv ntawm cov txheej gel: qhov nruab nrab ntawm qhov tawv ntawm 10 qhov kev tawg ntawm lub cev pwm ntsuas yog ntau dua 35.

7. Qhov xwm txheej ntawm pwm tsis tas yuav muaj npuas ntawm qhov chaw ntawm pwm, tsis pub ntau tshaj 3 npuas hauv 1m2 ntawm cov npuas pom hauv lub tsho gel thiab pwm laminate; tsis muaj cov cim txhuam pom tseeb, khawb thiab kho cov cim ntawm qhov chaw ntawm pwm, thiab tsis pub ntau tshaj 5 lub qhov hauv 1m2 ntawm qhov chaw. A, yuav tsis muaj qhov tshwm sim txheej.

8. Lub thav duab hlau ntawm lub pwm yog qhov tsim nyog, thiab nws yuav tsum muaj cov qauv thav duab tag nrho. Lub platform clamping yuav tsum ruaj khov thiab tsis yooj yim deformed; lub cuab yeej hydraulic qhib thiab kaw du thiab du, qhov ceev yog adjustable, thiab lub qhov hloov pauv mus ncig tau muab, uas tuaj yeem ua tau raws li lub sijhawm qhib thiab kaw > 1000 zaug hauv kev siv ib txwm.

9. Cov pwm yog tsim raws li cov txheej txheem nqus tsev, qhov tuab ntawm lub cev tseem ceeb yuav tsum ncav cuag 15 hli, thiab qhov tuab ntawm lub flange ntawm cov pwm yuav tsum yog ≥18 hli.

10. Cov pins ntawm cov pwm yog cov pins hlau, thiab cov pins thiab cov khoom FRP yuav tsum tau kaw.

11. Cov kab txiav ntawm cov pwm raug tshuaj xyuas nruj me ntsis raws li tus qauv khoom.

12. Qhov loj sib phim ntawm cov pwm yuav tsum yog qhov tseeb, thiab qhov yuam kev sib phim ntawm cov khoom sib phim yuav tsum yog ≤1.5 hli.

13. Lub neej ua haujlwm ib txwm ntawm cov pwm yuav tsum tsis pub tsawg dua 500 pawg khoom.

14. Qhov tiaj tiaj ntawm cov pwm yog ± 0.5 hli ib lub 'meter' linear, thiab yuav tsum tsis muaj qhov tsis sib xws.

15. Txhua qhov loj ntawm cov pwm tau lees tias muaj qhov yuam kev ntawm ± 1 hli, thiab tsis muaj burr ntawm qhov chaw ntawm lub laminate.

16. Qhov chaw ntawm pwm tsis pub muaj qhov tsis zoo xws li pinholes, txiv kab ntxwv tev tawv, sandpaper khawb, qaib taw tawg, thiab lwm yam, thiab lub arc yuav tsum du.

17. Cov pwm raug kho tom qab ntawm qhov kub siab ntawm 80 ° C, thiab demolded tom qab 8 teev.

18. Cov pwm tsis tuaj yeem hloov pauv nyob rau hauv qhov kub siab tshaj plaws ntawm 90 ℃ -120 ℃, thiab qhov chaw tsis tuaj yeem tshwm sim cov cim ntsws, tawg, thiab tsis sib luag.

19. Yuav tsum muaj qhov sib txawv ntau tshaj 10 hli ntawm lub thav duab hlau thiab lub pwm, thiab qhov sib koom ua ke ntawm ob lub cev yuav tsum tau muab cov cork lossis ntau txheej boards ntawm tib lub thickness.

20. Qhov sib koom ua ke ntawm cov pwm sib cais tsis tuaj yeem raug tshem tawm, qhov tsim pwm tsim nyog, cov pwm raug tso tawm, kev ua haujlwm khoom yooj yim, thiab cov pwm yooj yim tso tawm.

21. Qhov siab tsis zoo ntawm cov pwm yog raug rau 0.1, thiab qhov siab raug tswj hwm rau 5 feeb.

Lub sijhawm tshaj tawm: Lub Peb Hlis-22-2022