Tus qauv tsim khoom Suav teb zoo tshaj plaws E-iav lub teeb hnyav chopped strand fiberglass lev

Txhawm rau kom tau raws li qhov xav tau ntawm cov neeg siv khoom, peb txhua txoj haujlwm raug ua tiav raws li peb cov lus hais "Zoo Tshaj, Tus Nqi Sib Tw, Kev Pabcuam Sai" rau Tus Qauv Tsim Khoom Tuam Tshoj Zoo Tshaj Plaws E-Glass Lub Teeb Nyhav Chopped Strand Fiberglass Mat, Peb xav siv lub sijhawm no los xyuas kom meej txog kev sib raug zoo ntev nrog cov neeg siv khoom los ntawm thoob plaws lub ntiaj teb.

Txhawm rau kom ua tau raws li cov neeg siv khoom xav tau zoo tshaj plaws, peb cov haujlwm txhua yam raug ua raws li peb lub ntsiab lus "Zoo Tshaj, Tus Nqi Sib Tw, Kev Pabcuam Ceev" rauTuam Tshoj Fiberglass Mats, Cov Mats Txiav, Peb cov haujlwm ua lag luam thiab cov txheej txheem tau tsim los xyuas kom meej tias peb cov neeg siv khoom muaj kev nkag mus rau ntau yam khoom nrog lub sijhawm luv tshaj plaws. Qhov kev ua tiav no tau ua tiav los ntawm peb pab neeg muaj kev txawj ntse thiab kev paub dhau los. Peb nrhiav cov neeg uas xav loj hlob nrog peb thoob plaws ntiaj teb thiab sawv tawm ntawm cov neeg coob coob. Tam sim no peb muaj cov neeg uas txais tos tag kis, muaj lub zeem muag, nyiam ncab lawv lub siab thiab mus deb tshaj qhov lawv xav tias ua tau.

E-Iav Hmoov Chopped Strand Mat yog ua los ntawm cov xov txiav faib ua ntu zus uas tuav ua ke los ntawm cov hmoov binder. Nws sib xws nrog UP, VE, EP, PF resins. Qhov dav ntawm yob yog txij li 50mm txog 3300mm.

Cov yam ntxwv ntawm cov khoom

● Kev tawg sai hauv styrene

● Lub zog tensile siab, tso cai rau kev siv hauv kev teeb tsa tes los tsim cov khoom loj hauv thaj chaw

● Zoo ntub dej thiab ntub dej sai hauv cov resins, cua nkag sai

● Kev tiv thaiv xeb zoo heev

Daim Ntawv Thov

Nws cov ntawv thov siv kawg suav nrog cov nkoj, cov khoom siv da dej, cov khoom siv tsheb, cov kav dej tiv taus tshuaj lom neeg, cov tank, cov pej thuam txias thiab cov khoom siv hauv tsev

Tej zaum yuav muaj lwm yam kev thov ntxiv txog lub sijhawm ntub thiab lub sijhawm lwj thaum thov. Nws yog tsim los siv rau hauv kev teeb tsa tes, kev sib txuas ntawm cov xov hlau, kev sib txuas molding thiab cov txheej txheem laminating tas mus li.

Cov Lus Qhia Txog Khoom

| Vaj tse | Qhov Hnyav ntawm Cheeb Tsam | Cov ntsiab lus noo noo | Cov Ntsiab Lus Loj | Lub zog tawg | Dav |

| (%) | (%) | (%) | (N) | (mm) | |

| Vaj tse | IS03374 | ISO3344 | ISO1887 | ISO3342 | 50-3300 |

| EMC80P | ±7.5 | ≤0.20 | 8-12 | ≥40 | |

| EMC100P | ≥40 | ||||

| EMC120P | ≥50 | ||||

| EMC150P | 4-8 | ≥50 | |||

| EMC180P | ≥60 | ||||

| EMC200P | ≥60 | ||||

| EMC225P | ≥60 | ||||

| EMC300P | 3-4 | ≥90 | |||

| EMC450P | ≥120 | ||||

| EMC600P | ≥150 | ||||

| EMC900P | ≥200 |

Cov lus qhia tshwj xeeb tuaj yeem tsim tawm raws li cov neeg siv khoom xav tau.

Cov Txheej Txheem Tsim Khoom

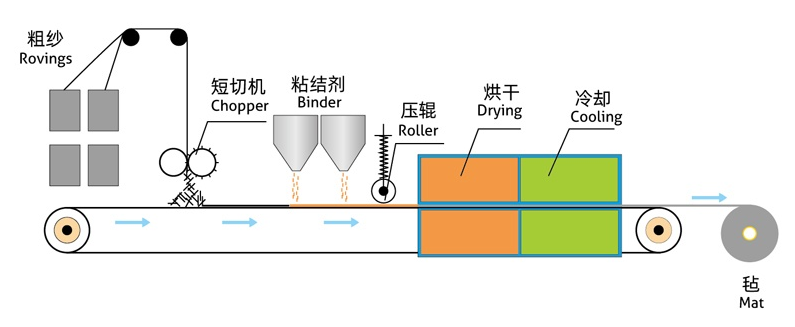

Cov khoom sib dhos ua ke raug txiav kom ntev raws li qhov tau teev tseg, thiab tom qab ntawd poob rau ntawm lub tshuab xa khoom yam tsis tau npaj tseg.

Cov xov txiav raug sib txuas ua ke los ntawm cov khoom siv emulsion lossis cov khoom siv hmoov.

Tom qab ziab, txias thiab qhwv, ib daim lev txiav tau tsim.

Ntim Khoom

Txhua daim lev uas raug txiav lawm raug qhwv rau ntawm ib lub raj ntawv uas muaj txoj kab uas hla sab hauv yog 76 hli thiab daim lev yob muaj txoj kab uas hla 275 hli. Daim lev yob raug qhwv nrog zaj duab xis yas, thiab tom qab ntawd ntim rau hauv lub thawv ntawv lossis qhwv nrog ntawv kraft. Cov lev tuaj yeem muab tso rau ntsug lossis kab rov tav. Rau kev thauj mus los, cov lev tuaj yeem thauj mus rau hauv lub thawv ncaj qha lossis ntawm cov pallets.

Kev Khaws Cia

Tshwj tsis yog hais lwm yam, Chopped Strand Mat yuav tsum khaws cia rau hauv qhov chaw qhuav, txias thiab tsis txhob los nag. Nws raug pom zoo kom tswj qhov kub thiab txias hauv chav tsev ntawm 15 ℃ ~ 35 ℃ thiab 35% ~ 65% feem.

Txhawm rau kom tau raws li qhov xav tau ntawm cov neeg siv khoom, peb txhua txoj haujlwm raug ua tiav raws li peb cov lus hais "Zoo Tshaj, Tus Nqi Sib Tw, Kev Pabcuam Sai" rau Tus Qauv Tsim Khoom Tuam Tshoj Zoo Tshaj Plaws E-Glass Lub Teeb Nyhav Chopped Strand Fiberglass Mat, Peb xav siv lub sijhawm no los xyuas kom meej txog kev sib raug zoo ntev nrog cov neeg siv khoom los ntawm thoob plaws lub ntiaj teb.

Tus qauv tsim khoomTuam Tshoj Fiberglass Mats, Cov Mats Txiav, Peb cov haujlwm ua lag luam thiab cov txheej txheem tau tsim los xyuas kom meej tias peb cov neeg siv khoom muaj kev nkag mus rau ntau yam khoom nrog lub sijhawm luv tshaj plaws. Qhov kev ua tiav no tau ua tiav los ntawm peb pab neeg muaj kev txawj ntse thiab kev paub dhau los. Peb nrhiav cov neeg uas xav loj hlob nrog peb thoob plaws ntiaj teb thiab sawv tawm ntawm cov neeg coob coob. Tam sim no peb muaj cov neeg uas txais tos tag kis, muaj lub zeem muag, nyiam ncab lawv lub siab thiab mus deb tshaj qhov lawv xav tias ua tau.