FRP Vaj Huam Sib Luag

Kev piav qhia txog khoom

FRP (tseem hu ua iav fiber reinforced yas, luv luv li GFRP lossis FRP) yog cov khoom siv ua haujlwm tshiab ua los ntawm cov khoom siv hluavtaws thiab iav fiber los ntawm cov txheej txheem sib xyaw.

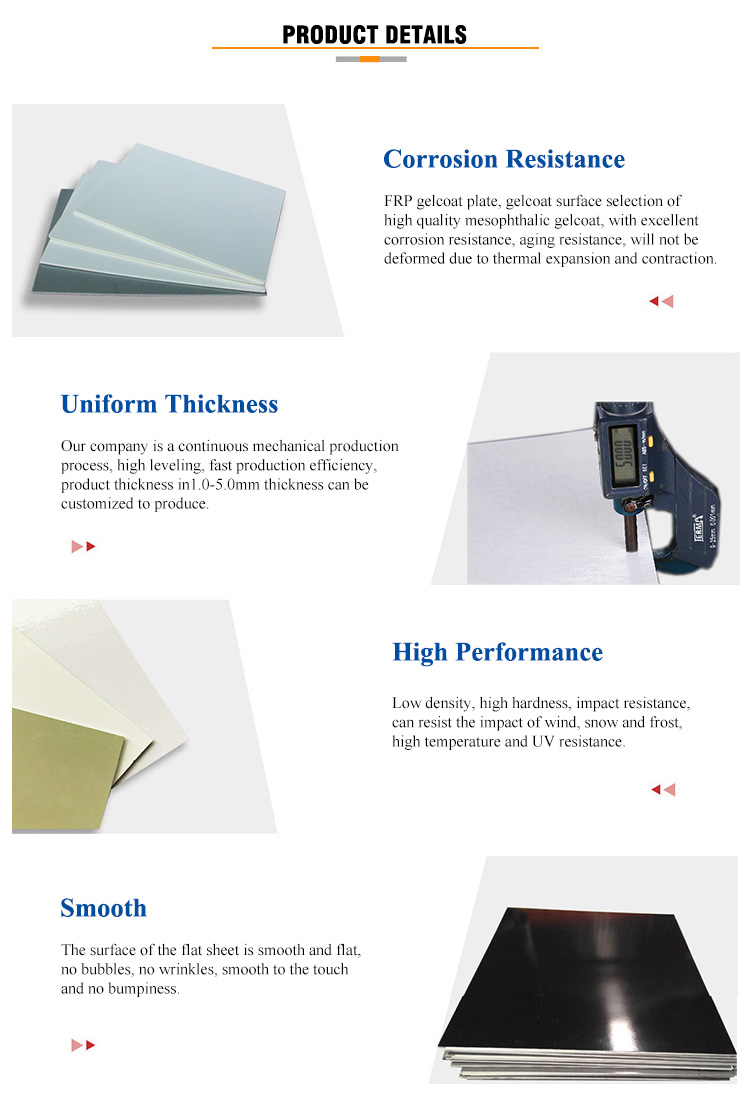

Daim ntawv FRP yog cov khoom siv thermosetting polymer nrog cov yam ntxwv hauv qab no:

(1) lub teeb yuag thiab lub zog siab.

(2) Kev tiv thaiv corrosion zoo FRP yog cov khoom siv tiv thaiv corrosion zoo.

(3) Cov khoom siv hluav taws xob zoo yog cov ntaub ntawv rwb thaiv tsev zoo heev, siv los tsim cov insulators.

(4) Cov khoom siv thermal zoo FRP muaj cov thermal conductivity tsawg.

(5) Tsim tau zoo

(6) Kev ua tau zoo heev

Cov ntawv thov:

Siv dav hauv cov tsev, chaw cia khoom khov thiab tub yees, chaw cia khoom txias, chaw cia tsheb ciav hlau, chaw cia tsheb npav, nkoj, chaw ua zaub mov noj, khw noj mov, chaw tsim tshuaj, chaw soj nstuam, tsev kho mob, chav dej, tsev kawm ntawv thiab lwm qhov chaw xws li phab ntsa, partitions, qhov rooj, qab nthab dai, thiab lwm yam.

| Kev ua tau zoo | Chav tsev | Cov Ntawv Pultruded | Cov Tuav Pultruded | Cov Hlau Ua Vaj Tse | Aluminium | Rigid Polyvinyl chloride |

| Qhov Ceev | T/M3 | 1.83 | 1.87 | 7.8 | 2.7 | 1.4 |

| Lub zog tensile | Mpa | 350-500 | 500-800 | 340-500 | 70-280 | 39-63 |

| Cov qauv ntawm elasticity ntawm lub zog | Gpa | 18-27 | 25-42 | 210 | 70 | 2.5-4.2 |

| Lub zog khoov | Mpa | 300-500 | 500-800 | 340-450 | 70-280 | 56-105 |

| Cov qauv ntawm elasticity ntawm flexural | Gpa | 9~16 | 25-42 | 210 | 70 | 2.5-4.2 |

| Coefficient ntawm thermal expansion | 1/℃ × 105 | 0.6-0.8 | 0.6-0.8 | 1.1 | 2.1 | 7 |