Fibeglass Reinforced Thermoplastic Assembeld Roving nrog PBT / PET, ABS Resin rau FRP Qhov Chaw

Sib Dhos Roving rau thermoplastic yog coated nrog silane-based sizing sib xws nrog ntau lub tshuab resin xws li PP, AS / ABS, tshwj xeeb tshaj yog reinforcing PA rau zoo hydrolysis resistant.

Nta:

- Cov khoom siv kho tshuab zoo heev thiab tiv taus hydrolysis rau PA

- Qhov ci ntsa iab ntawm cov khoom sib xyaw ua ke tsis muaj fiber tau qhia tawm.

- Du thiab qis fuzz rau huab cua ua haujlwm zoo.

- Cov khoom siv sib xws rau cov khoom kawg nrog cov ntsiab lus iav sib xws.

- Tau tshaj nrog ntau lub kaw lus cob xws li PP, AS / ABS.

| Kev txheeb xyuas | |

| Hom Iav | E |

| Sib dhos Roving | R |

| Txoj kab uas hla ntawm lub ntsiab lus, μm | 11, 13, 14 |

| Linear Density, tex | 2000 xyoo |

| Cov Kev Ntsuas Kev Txawj | |||

| Qhov Ceev Tawm (%) | Cov ntsiab lus noo noo (%) | Qhov Loj Cov Ntsiab Lus (%) | Kev nruj (hli) |

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ±5 | ≤0.10 | 0.90 ± 0.15 | 130 ± 20 |

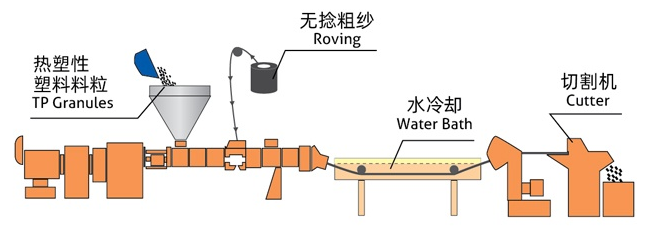

Extrusion thiab Hauvjkev txiav txim Cov Txheej Txheem

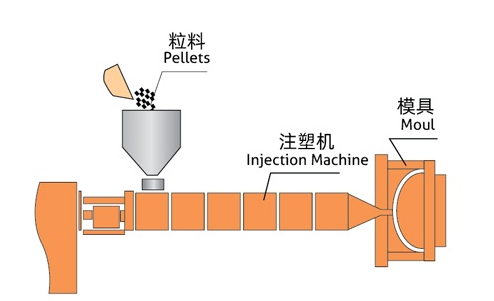

Cov khoom siv txhawb nqa (iav fiber roving) thiab thermoplastic resin raug sib xyaw rau hauv lub tshuab extruder Tom qab txias, lawv raug txiav ua cov thermoplastic pellets txhawb nqa. Cov pellets raug pub rau hauv lub tshuab txhaj tshuaj molding los tsim cov khoom tiav.

Daim Ntawv Thov

E-iav Sib Dhos Roving Rau Thermoplastics feem ntau yog tsim los rau cov txheej txheem extrusion twin-screw los tsim cov thermoplastic granules. Cov ntawv thov tseem ceeb suav nrog cov khoom siv khi txoj kev tsheb ciav hlau, cov khoom siv tsheb, cov ntawv thov hluav taws xob & hluav taws xob.