E-iav Sib Dhos Roving Rau Tshuaj Tsuag

E-iav Sib Dhos Roving Rau Tshuaj Tsuag

Cov Khoom Siv Roving Sib Dhos rau kev txau yog sib xws nrog UP thiab VE resins. Nws muab cov khoom ntawm qhov tsis tshua muaj zog, kev sib kis zoo heev, thiab kev ntub dej zoo hauv cov resins.

Cov yam ntxwv

●Tsis tshua muaj zog

●Kev sib kis zoo heev

● Cov dej noo zoo hauv cov resins

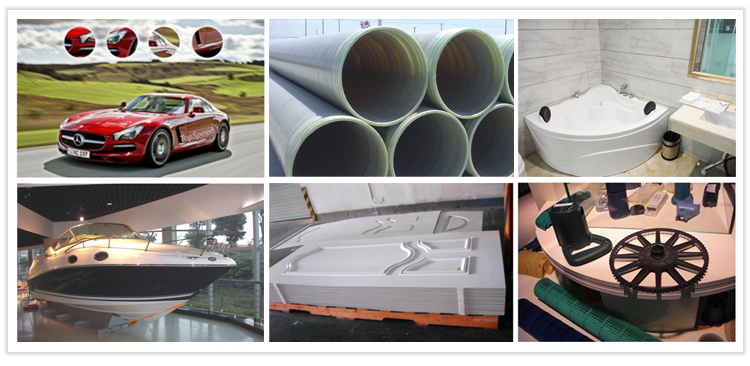

Daim Ntawv Thov

Nws npog ntau yam kev siv: lub dab da dej, FRP lub cev nkoj, ntau yam kav dej, cov hlab cia khoom thiab cov pej thuam txias.

Daim Ntawv Teev Khoom

| Khoom | Kev Ceev Nruag | Kev Sib Tw Sib Xws ntawm Cov Roj Hmab | Cov yam ntxwv | Siv Thaum Kawg |

| BHSU-01A | 2400, 4800 | UP, VE | sai ntub tawm, yooj yim dov tawm, zoo tshaj plaws dispersion | lub dab da dej, cov khoom txhawb nqa |

| BHSU-02A | 2400, 4800 | UP, VE | yooj yim dov tawm, tsis muaj caij nplooj ntoos hlav rov qab | cov khoom siv hauv chav dej, cov khoom siv nkoj |

| BHSU-03A | 2400, 4800 | UP, VE, PU | sai sai ntub tawm, zoo heev mechanical thiab dej tsis kam | lub dab da dej, FRP nkoj hull |

| BHSU-04A | 2400, 4800 | UP, VE | qhov ceev ntawm qhov ntub dej nruab nrab | pas dej ua luam dej, lub dab da dej |

| Kev txheeb xyuas | |

| Hom Iav | E |

| Sib dhos Roving | R |

| Txoj kab uas hla ntawm lub ntsiab lus, μm | 11, 12, 13 |

| Linear Density, tex | 2400, 3000 |

| Cov Kev Ntsuas Kev Txawj | |||

| Qhov Ceev Tawm (%) | Cov ntsiab lus noo noo (%) | Qhov Loj Cov Ntsiab Lus (%) | Kev nruj (hli) |

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ±5 | ≤0.10 | 1.05 ± 0.15 | 135 ± 20 |

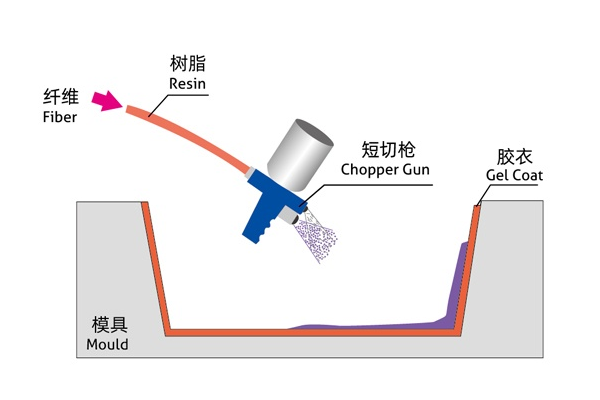

Cov txheej txheem txau

Ib lub pwm raug txau nrog cov tshuaj sib xyaw ntawm cov tshuaj catalyzed resin thiab cov fiberglass roving txiav (fiberglass txiav rau qhov ntev tshwj xeeb siv rab phom chopper). Tom qab ntawd cov iav-resin sib xyaw raug compacted zoo, feem ntau yog manually, rau kev impregnation tiav thiab deairing. Tom qab kho cov khoom sib xyaw tiav lawm raug de-molded.