Kev Roving Ncaj Qha Rau CFRT

Kev Roving Ncaj Qha Rau CFRT

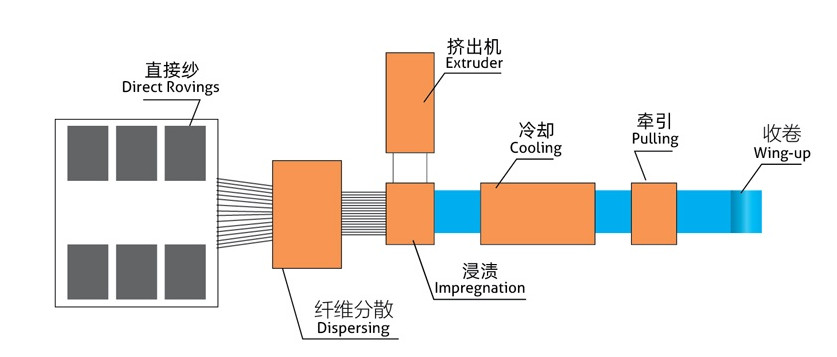

Kev Roving Ncaj Qha rau Cov Khoom Siv Thermoplastics Uas Muaj Cov Fiber Ntau Ntxiv tas mus li yog siv rau cov txheej txheem CFRT. Cov xov paj fiberglass tau tawm sab nraud los ntawm cov bobbins ntawm lub txee thiab tom qab ntawd teeb tsa tib qho kev coj ua; Cov xov paj tau tawg los ntawm kev nruj thiab cua sov los ntawm cua kub lossis IR; Molten thermoplastic compound tau muab los ntawm lub extruder thiab impregnated lub fiberglass los ntawm kev siab; Tom qab txias, daim ntawv CFRT kawg tau tsim.

Cov yam ntxwv

●Tsis muaj suab nrov

● Kev sib raug zoo nrog ntau lub tshuab resin

●Kev ua haujlwm zoo

●Kev sib kis zoo heev

● Cov khoom siv kho tshuab zoo heev

Daim Ntawv Thov:

Nws yog siv los ua tsheb, kev tsim kho, kev thauj mus los thiab kev caij dav hlau.

Daim Ntawv Teev Khoom

| Khoom | Kev Ceev Nruag | Kev Sib Tw Sib Xws ntawm Cov Roj Hmab | Cov yam ntxwv | Siv Thaum Kawg |

| BHCFRT-01D | 300-2400 | PA, PBT, PET, TPU, ABS | Kev sib raug zoo nrog ntau yam ntawm cov txheej txheem resin, qis fuzz | tsheb, kev tsim kho, kev thauj mus los thiab kev caij dav hlau |

| BHCFRT-02D | 400-2400 | PP, PE | Kev tawg zoo heev, cov khoom siv kho tshuab zoo heev | tsheb, kev tsim kho, kev ua si nawv, hluav taws xob, thiab hluav taws xob |

| Kev txheeb xyuas | ||||

| Hom Iav | E | |||

| Kev Rov Qab Ncaj Qha | R | |||

| Txoj kab uas hla ntawm lub ntsiab lus, μm | 400 | 600 | 1200 | 2400 |

| Linear Density, tex | 16 | 16 | 17 | 17 |

| Cov Kev Ntsuas Kev Txawj | |||

| Qhov Ceev Tawm (%) | Cov ntsiab lus noo noo (%) | Qhov Loj Cov Ntsiab Lus (%) | Lub zog tawg (N/Tex) |

| ISO1889 | ISO3344 | ISO1887 | IS03341 |

| ±5 | ≤0.10 | 0.55 ± 0.15 | ≥0.3 |

Cov Txheej Txheem CFRT

Ib qho sib tov ntawm cov polymer resin thiab cov khoom ntxiv tau txais los ntawm kev extruder. Cov filament roving tas mus li yog dispersed thiab impregnated los ntawm rub los ntawm cov sib tov molten Tom qab txias, kho thiab coiling. Cov khoom kawg yog tsim