Tuam Tshoj Lag Luam Wholesale Tuam Tshoj Siab Zoo Qhov Zoo Flowability Siv Hauv Skis thiab Ncej Fiberglass Chopped Strands rau Koob Mat

Peb muaj cov khoom siv tsim khoom zoo tshaj plaws, cov kws ua haujlwm thiab cov neeg ua haujlwm uas muaj kev paub dhau los thiab tsim nyog, suav tias yog cov txheej txheem zoo nrog rau pab pawg neeg tau nyiaj txiag zoo ua ntej / tom qab muag rau Tuam Tshoj Lag Luam Wholesale Tuam Tshoj High Surface Quality Good Flowability Siv Hauv Skis thiab Poles Fiberglass Chopped Strands rau Koob Mat, Peb txais tos cov neeg yuav khoom tshiab thiab yav dhau los los ntawm txhua qhov chaw ntawm lub neej txhua hnub kom tiv tauj peb rau kev sib tham yav tom ntej thiab kev sib koom tes ua tiav!

Peb muaj cov khoom siv tsim khoom zoo tshaj plaws, cov engineers thiab cov neeg ua haujlwm uas muaj kev paub dhau los thiab tsim nyog, suav tias yog cov txheej txheem zoo nrog rau pab pawg neeg tau nyiaj txiag zoo ua ntej / tom qab muag kev txhawb nqa rauTuam Tshoj Fiberglass Chopped Strands rau Koob Mat, Cov Khoom Siv Fiberglass Nrov Tshaj Plaws Uas Muaj Cov Khoom Siv Kub Muag, Peb txoj kev txawj ntse, kev pabcuam zoo rau cov neeg siv khoom, thiab cov khoom lag luam tshwj xeeb ua rau peb / lub tuam txhab lub npe yog thawj qhov kev xaiv ntawm cov neeg siv khoom thiab cov muag khoom. Peb tau nrhiav koj qhov kev nug. Cia peb teeb tsa kev koom tes tam sim no!

Cov hlua khi rau Thermoplastic yog raws li tus neeg sawv cev silane coupling thiab cov qauv tsim tshwj xeeb, sib xws nrog PA, PBT / PET, PP, AS / ABS, PC, PPS / PPO, POM, LCP.

E-Iav Chopped Stands rau thermoplastic paub txog kev ua tiav zoo heev, kev ntws zoo dua thiab cov khoom ua tiav, xa cov khoom siv kho tshuab zoo heev thiab qhov zoo ntawm qhov chaw rau nws cov khoom tiav.

Cov yam ntxwv ntawm cov khoom

1. Tus neeg sawv cev sib txuas ua ke raws li Silane uas xa cov khoom sib npaug zoo tshaj plaws.

2. Kev tsim cov qauv tshwj xeeb uas xa cov kev sib txuas zoo ntawm cov xov txiav thiab cov matrix resin

3. Kev ncaj ncees zoo heev thiab kev ntws qhuav, muaj peev xwm pwm zoo thiab kev sib kis

4. Cov khoom siv kho tshuab zoo heev thiab qhov chaw ntawm cov khoom sib xyaw

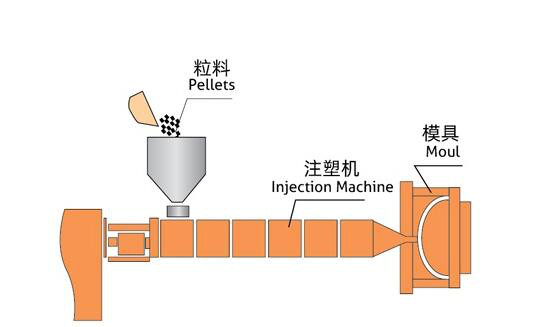

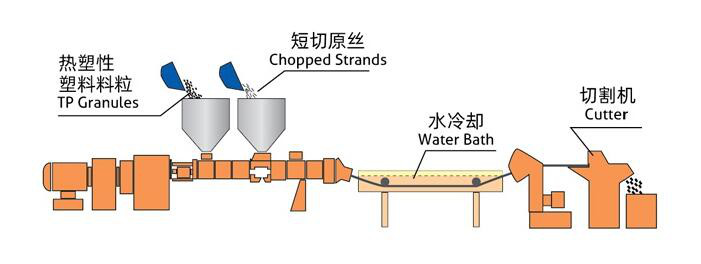

Cov Txheej Txheem Extrusion thiab Txhaj Tshuaj

Cov khoom siv txhawb nqa (cov iav fiber txiav cov xov) thiab cov thermoplastic resin raug sib xyaw rau hauv lub tshuab extruder. Tom qab txias, lawv raug txiav ua cov pellets thermoplastic uas muaj zog. Cov pellets raug pub rau hauv lub tshuab txhaj tshuaj molding kom ua cov khoom tiav.

Daim Ntawv Thov

E-iav Chopped Strands rau Thermoplastics feem ntau yog siv rau hauv kev txhaj tshuaj thiab kev nias molding cov txheej txheem thiab nws cov ntawv thov siv kawg suav nrog tsheb, khoom siv hauv tsev, li qub, twj tso kua mis tsev, tshuaj tiv thaiv corrosion thiab cov khoom siv kis las.

Daim Ntawv Teev Khoom:

| Khoom No. | Txiav Ntev, hli | Kev Sib Tw Sib Xws ntawm Cov Roj Hmab | Cov yam ntxwv |

| BH-01 | 3,4.5 | PP | Lub hom phiaj dav dav |

| BH-02 | 3,4.5 | AS, ABS | Lub hom phiaj dav dav |

| BH-03 | 3,4.5 | Tus tsiaj, PBT | Lub hom phiaj dav dav |

| BH-04 | 3,4.5 | Tus tsiaj, PBT | Tiv taus hluav taws xob |

| BH-05 | 3,4.5 | PA6, PA66 | Lub hom phiaj dav dav |

| BH-06 | 3,4.5 | PA6, PA66 | Tsis kam hydrolysis, ci ntsa iab zoo heev |

| BH-07 | 3,4.5 | PBT, TSIAJ | Kev ntws zoo |

Kev txheeb xyuas

| Hom Iav | E |

| Cov xov txiav | CS |

| Txoj kab uas hla ntawm lub ntsiab lus, μm | 13 |

| Txiav Ntev, hli | 4.5 |

Cov Kev Ntsuas Kev Txawj

| Txoj kab uas hla ntawm lub ntsiab lus (%) | Cov ntsiab lus noo noo (%) | Cov Ntsiab Lus Loj (%) | Qhov ntev ntawm kev txiav (hli) |

| ±10 | ≤0.10 | 0.50 ± 0.15 | ±1.0 |

Peb muaj cov khoom siv tsim khoom zoo tshaj plaws, cov kws ua haujlwm thiab cov neeg ua haujlwm uas muaj kev paub dhau los thiab tsim nyog, suav tias yog cov txheej txheem zoo nrog rau pab pawg neeg tau nyiaj txiag zoo ua ntej / tom qab muag rau Tuam Tshoj Lag Luam Wholesale Tuam Tshoj High Surface Quality Good Flowability Siv Hauv Skis thiab Poles Fiberglass Chopped Strands rau Koob Mat, Peb txais tos cov neeg yuav khoom tshiab thiab yav dhau los los ntawm txhua qhov chaw ntawm lub neej txhua hnub kom tiv tauj peb rau kev sib tham yav tom ntej thiab kev sib koom tes ua tiav!

Tuam Tshoj Lag Luam WholesaleTuam Tshoj Fiberglass Chopped Strands rau Koob Mat, Cov Khoom Siv Fiberglass Nrov Tshaj Plaws Uas Muaj Cov Khoom Siv Kub Muag, Peb txoj kev txawj ntse, kev pabcuam zoo rau cov neeg siv khoom, thiab cov khoom lag luam tshwj xeeb ua rau peb / lub tuam txhab lub npe yog thawj qhov kev xaiv ntawm cov neeg siv khoom thiab cov muag khoom. Peb tau nrhiav koj qhov kev nug. Cia peb teeb tsa kev koom tes tam sim no!