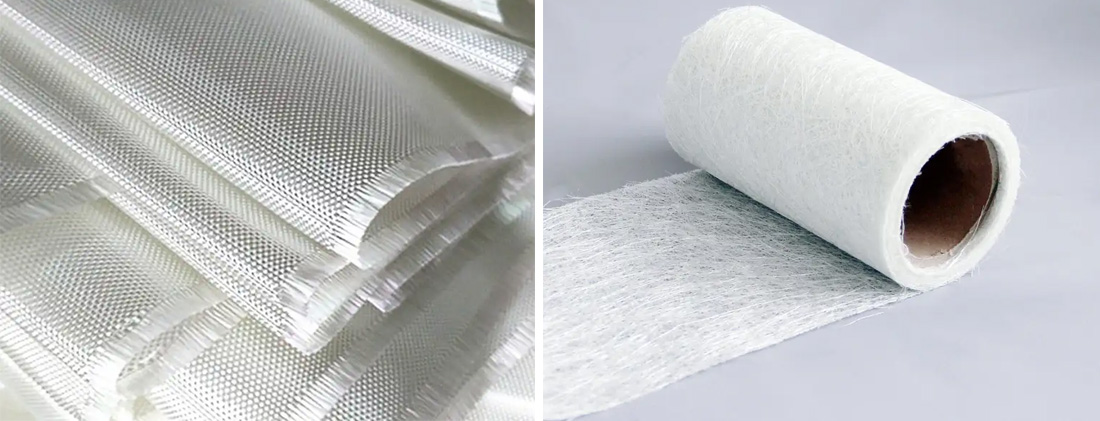

Cov Iav Fiber Mats

1.Cov lev txiav (CSM)Kev siv cov iav fiber roving(qee zaum kuj txuas ntxiv mus) raug txiav ua 50 hli ntev, tsis sib xws tab sis sib npaug zos tso rau ntawm txoj siv sia conveyor mesh. Tom qab ntawd siv cov emulsion binder, lossis cov hmoov binder raug plua plav rau, thiab cov khoom raug cua sov thiab kho kom tsim cov lev txiav. CSM feem ntau yog siv rau hauv kev teeb tsa tes, kev ua vaj huam sib luag txuas ntxiv, kev sib phim tuag molding, thiab SMC (Sheet Molding Compound) cov txheej txheem. Cov kev cai zoo rau CSM suav nrog:

- Qhov hnyav sib npaug thoob plaws qhov dav.

- Kev faib cov xov txiav sib npaug zos rau ntawm qhov chaw ntawm daim lev uas tsis muaj qhov khoob loj, thiab kev faib cov ntawv sib npaug zos.

- Lub zog ntawm daim lev qhuav nruab nrab.

- Cov khoom siv resin zoo heev thiab nkag mus tau zoo.

2.Cov ntaub pua plag txuas ntxiv (CFM)Cov iav fiber txuas ntxiv uas tsim thaum lub sijhawm kos duab lossis unwound los ntawm cov pob khoom roving raug muab tso rau hauv daim duab-yim tus qauv ntawm txoj siv sia uas txav mus los tas li thiab khi nrog cov hmoov binder. Txij li thaum cov fibers hauv CFM txuas ntxiv mus, lawv muab kev txhawb nqa zoo dua rau cov ntaub ntawv sib xyaw dua li CSM. Nws feem ntau yog siv rau hauv pultrusion, RTM (Resin Transfer Molding), lub hnab siab molding, thiab GMT (Glass Mat Reinforced Thermoplastics) cov txheej txheem.

3.Cov ntaub pua plag saum npooCov khoom FRP (Fiber Reinforced Plastic) feem ntau xav tau ib txheej nto uas muaj cov resin ntau, uas feem ntau ua tiav los ntawm kev siv cov iav nruab nrab-alkali (C-iav) surfacing lev. Vim tias daim lev no yog ua los ntawm C-iav, nws muab FRP nrog kev tiv thaiv tshuaj lom neeg, tshwj xeeb tshaj yog kev tiv thaiv acid. Tsis tas li ntawd, vim nws nyias thiab cov fiber ntau dua, nws tuaj yeem nqus tau ntau cov resin los tsim ib txheej nplua nuj resin, npog cov qauv ntawm cov iav fiber reinforcing cov ntaub ntawv (xws li woven roving) thiab ua haujlwm ua qhov tiav nto.

4.Cov lev uas muaj koobMuaj peev xwm muab faib ua Chopped Fiber Needled Mat thiab Continuous Filament Needled Mat.

- Cov lev uas muaj cov xov fiber ntauyog ua los ntawm kev txiav cov iav fiber roving mus rau hauv 50mm ntev, random tso lawv rau ntawm ib lub substrate uas tau muab tso rau ntawm txoj siv conveyor, thiab tom qab ntawd koob nws nrog koob barbed. Cov koob thawb cov fibers txiav rau hauv lub substrate, thiab cov barbs kuj coj qee cov fibers, tsim ib qho qauv peb-seem. Lub substrate siv tuaj yeem yog cov ntaub woven xoob ntawm iav lossis lwm yam fibers. Hom koob lev no muaj cov qauv zoo li xav. Nws cov kev siv tseem ceeb suav nrog cov ntaub ntawv rwb thaiv tsev thermal thiab acoustic, cov ntaub ntawv hauv pem teb, thiab cov ntaub ntawv lim dej. Nws kuj tuaj yeem siv rau hauv FRP ntau lawm, tab sis FRP tshwm sim muaj zog qis dua thiab qhov kev siv txwv.

- Cov Khoom Siv Uas Siv Tau Ntev Ntevyog ua los ntawm kev pov cov iav fiber txuas ntxiv mus rau ntawm txoj siv sia siv cov khoom siv nthuav filament, ua raws li kev siv koob nrog lub rooj tsavxwm koob los tsim ib daim lev nrog cov qauv fiber peb-seem sib xyaw. Daim lev no feem ntau yog siv rau hauv kev tsim cov ntawv thermoplastic stampable uas muaj iav fiber ntxiv rau.

5.Cov ntaub pua plag xawsCov iav fiber uas raug txiav ua tej daim ntev li ntawm 50 hli mus txog 60cm tuaj yeem xaws ua ke nrog lub tshuab xaws kom ua tau ib daim lev fiber txiav lossis ib daim lev fiber ntev. Tus thawj tuaj yeem hloov cov CSM uas raug khi ua ke ib txwm muaj hauv qee qhov kev siv, thiab tus tom kawg tuaj yeem hloov CFM rau qee qhov. Lawv cov txiaj ntsig zoo yog tsis muaj cov khi, zam kev ua qias tuaj thaum lub sijhawm tsim khoom, kev ua haujlwm zoo ntawm cov resin impregnation, thiab tus nqi qis dua.

Cov Khoom Siv Iav Fiber

Cov hauv qab no qhia txog ntau yam ntaub iav fiber ntau uas tau ua los ntawmcov iav fiber ntau.

1. Daim Ntaub IavCov ntaub iav uas tsim tawm hauv Suav teb tau muab faib ua cov alkali-free (E-iav) thiab medium-alkali (C-iav) hom; feem ntau cov khoom lag luam txawv teb chaws siv E-GLASS alkali-free iav ntaub. Cov ntaub iav feem ntau yog siv los tsim ntau yam hluav taws xob insulating laminates, luam tawm circuit boards, lub cev tsheb, cov thoob dej cia khoom, nkoj, pwm, thiab lwm yam. Cov ntaub iav nruab nrab-alkali feem ntau yog siv los tsim cov yas-coated ntim ntaub thiab rau cov ntawv thov corrosion-resistant. Cov yam ntxwv ntawm cov ntaub yog txiav txim siab los ntawm cov khoom fiber, warp thiab weft ceev, cov qauv xov paj, thiab weave qauv. Warp thiab weft ceev yog txiav txim siab los ntawm cov qauv xov paj thiab weave qauv. Kev sib xyaw ua ke ntawm warp thiab weft ceev thiab cov qauv xov paj txiav txim siab cov khoom siv lub cev ntawm cov ntaub, xws li qhov hnyav, thickness, thiab tawg lub zog. Muaj tsib cov qauv weave yooj yim: tiaj tus (zoo ib yam li woven roving), twill (feem ntau ± 45 °), satin (zoo ib yam li unidirectional ntaub), leno (lub ntsiab weave rau iav fiber mesh), thiab matts (zoo ib yam li oxford ntaub).

2.Daim kab xev iav fiberMuab faib ua daim kab xev woven-edge (edge selvage) thiab daim kab xev non-woven-edge (edge frayed). Tus qauv weave tseem ceeb yog tiaj tus. Daim kab xev fiber iav tsis muaj alkali feem ntau siv los tsim cov khoom siv hluav taws xob uas xav tau lub zog siab thiab cov khoom dielectric zoo.

3.Iav Fiber Unidirectional Npuag

- Unidirectional Warp Npuagyog ib daim ntaub plaub-harness tawg satin lossis ntev-shaft satin weave ntaub woven nrog coarse warp yarns thiab zoo weft yarns. Nws tus yam ntxwv yog siab zog feem ntau nyob rau hauv lub warp kev taw qhia (0 °).

- Kuj tseem muajIav Fiber Unidirectional Weft Npuag, muaj nyob rau hauv ob qho tib si warp-knitted thiab woven hom. Nws yog tus cwj pwm los ntawm coarse weft yarns thiab zoo warp yarns, nrog rau cov iav fiber yarns feem ntau oriented nyob rau hauv lub weft kev taw qhia, muab siab zog nyob rau hauv lub weft kev taw qhia (90 °).

4.Iav Fiber 3D Npuag (Stereoscopic Npuag)Cov ntaub 3D zoo ib yam li cov ntaub planar. Lawv cov yam ntxwv ntawm cov qauv tau hloov zuj zus los ntawm ib-seem thiab ob-seem mus rau peb-seem, ua rau cov ntaub ntawv sib xyaw ua ke uas lawv tau txhawb nqa zoo thiab ua kom haum, txhim kho qhov interlaminar shear zog thiab kev tiv thaiv kev puas tsuaj ntawm cov khoom sib xyaw. Lawv tau tsim los ua kom tau raws li qhov xav tau tshwj xeeb ntawm aerospace, aviation, riam phom, thiab marine sectors, thiab lawv daim ntawv thov tam sim no tau nthuav dav kom suav nrog tsheb, khoom siv kis las, thiab khoom siv kho mob. Muaj tsib pawg tseem ceeb: cov ntaub 3D woven, knitted 3D fabrics, orthogonal thiab non-orthogonal non-crimp 3D fabrics, 3D braided fabrics, thiab lwm yam ntaub 3D. Cov duab ntawm 3D fabrics suav nrog block, columnar, tubular, hollow truncated cone, thiab variable-thickness irregular cross-sections.

5. Cov Ntaub Iav Fiber Preform (Cov Ntaub Zoo Li)Cov duab ntawm cov ntaub preform zoo ib yam li cov duab ntawm cov khoom uas lawv xav kom txhawb nqa, thiab lawv yuav tsum tau xaws rau ntawm cov looms tshwj xeeb. Cov ntaub zoo sib xws suav nrog: lub kaus mom spherical, cones, kaus mom, dumbbell-zoo li cov ntaub, thiab lwm yam. Cov duab tsis sib xws xws li lub thawv thiab lub nkoj hulls kuj tuaj yeem tsim tau.

6.Cov Ntaub Iav Fiber Core (Ntawv Xaws Los Ntawm Qhov Tuab)Cov ntaub plawv muaj ob txheej ntaub sib luag uas txuas nrog los ntawm cov kab ntsug ntev. Nws cov duab txiav tuaj yeem yog peb ceg, plaub ceg, lossis honeycomb.

7.Cov Ntaub Iav Fiber Sib Txuas (Cov Ntaub Xaws Los Yog Cov Ntaub Xaws)Nws txawv ntawm cov ntaub ib txwm thiab los ntawm qhov kev xav ntawm daim lev ib txwm muaj. Cov ntaub uas sib txuas ua ke feem ntau yog tsim los ntawm kev muab ib txheej ntawm cov xov paj warp thiab ib txheej ntawm cov xov paj weft tso rau saum, thiab tom qab ntawd xaws ua ke los ua ib daim ntaub. Cov txiaj ntsig ntawm cov ntaub uas sib txuas ua ke suav nrog:

- Nws tuaj yeem ua rau lub zog tensile kawg, lub zog tiv thaiv delamination nyob rau hauv kev ntxhov siab, thiab lub zog flexural ntawm FRP laminates.

- Nws txo qhov hnyav ntawmCov khoom FRP.

- Qhov chaw tiaj tiaj ua rau FRP nto du.

- Nws ua kom yooj yim rau kev ua haujlwm tes thiab txhim kho kev ua haujlwm. Cov khoom siv txhawb zog no tuaj yeem hloov CFM hauv pultruded FRP thiab RTM, thiab tseem tuaj yeem hloov woven roving hauv centrifugal cast FRP yeeb nkab ntau lawm.

Lub sijhawm tshaj tawm: Lub Kaum Hli-22-2025